SYCJ010110A Equipment parameters

·Equipment size: 1750*700*2000mm

·Equipment voltage: AC220V 50Hz

·Equipment power: 2 Kw

·Equipment weight: 650 Kg

·Applicable wire types

·Various suture wires such as single-strand, multi-strand, PGA, and chemically synthesized wires.

·Applicable wire diameter: ≥0.15mm

·Cut wire length: adjustable from 200 to 1100mm

·Production cycle: for a 450mm product, the production cycle is 10 seconds per piece.

·Temperature adjustment: 0-400 degrees (can be freely adjusted according to production requirements)

·Recipe function: It has a recipe function package.

·Thermosetting function: It has a thermosetting function.

·Dispensing function: It has a dispensing and hardening function.

·Constant tension control: Yes (can be freely adjusted according to production requirements)

Product Overview

The fully automatic suture hardening and cutting equipment is specifically designed for medical sutures. It integrates the functions of cutting sutures such as single-strand, multi-strand, PGA, and chemically synthesized sutures, as well as hardening the ends of the sutures. The system supports the free switching between the heating hardening mode and the dispensing hardening mode, and is suitable for various suture wires including single-strand, multi-strand, PGA, and chemically synthesized ones. Through the fully automatic processes of feeding, hardening, cutting, and discharging, efficient and stable production can be achieved. The equipment is easy to operate and supports customized recipes, flexibly meeting a variety of technological requirements.

Product Features

● Applicable Wire Types

It is compatible with a variety of suture wires, including single-strand, multi-strand, PGA, and chemically synthesized wires. The applicable diameter range of the wires is ≥ 0.15mm.

● Dual-mode Hardening Technology

It integrates two modes: heating hardening and dispensing hardening, enabling free switching and meeting diverse hardening requirements.

● Constant Tensile Force Control Technology for Heating Hardening

During the heating hardening process, advanced constant tensile force control technology is applied to ensure that the suture thread always maintains a constant tension. This effectively guarantees the quality and effect of suture thread hardening and improves the stability and durability of the product.

● Advanced Recipe Function – Flexible Customization and Wide Compatibility

Equipped with an advanced recipe function, it supports the customization of production process parameters, flexibly responds to various production processes and working conditions, and has strong compatibility.

● Efficient and Convenient Operation

It simplifies the operation process, improves work efficiency, and perfectly adapts to a fast and efficient production environment.

Dongguan Fortune Medical Technology Co., Ltd. (Introduction to absorbable polymer materials)

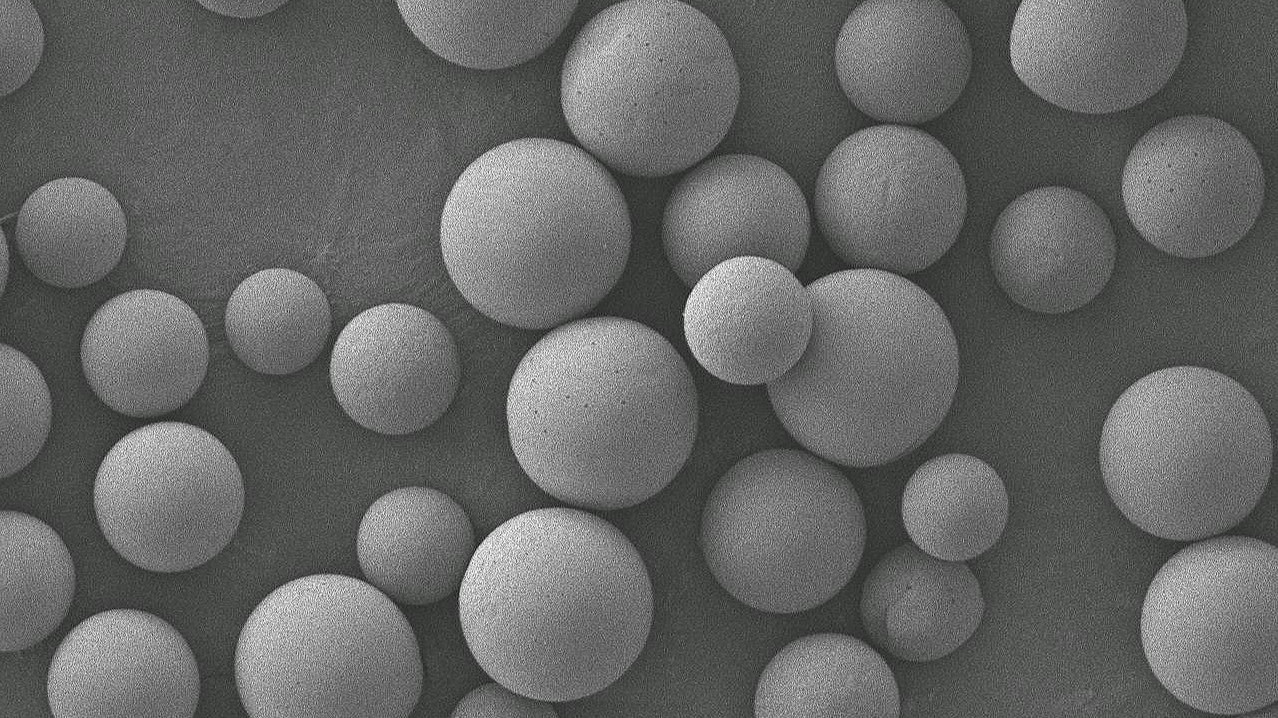

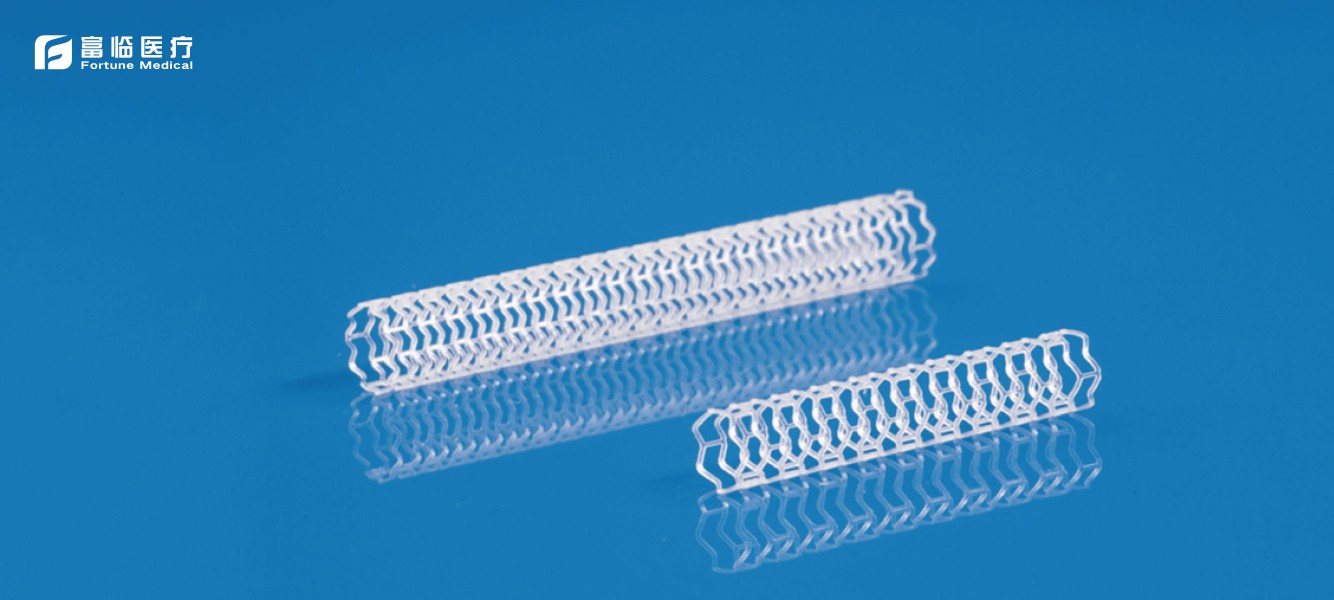

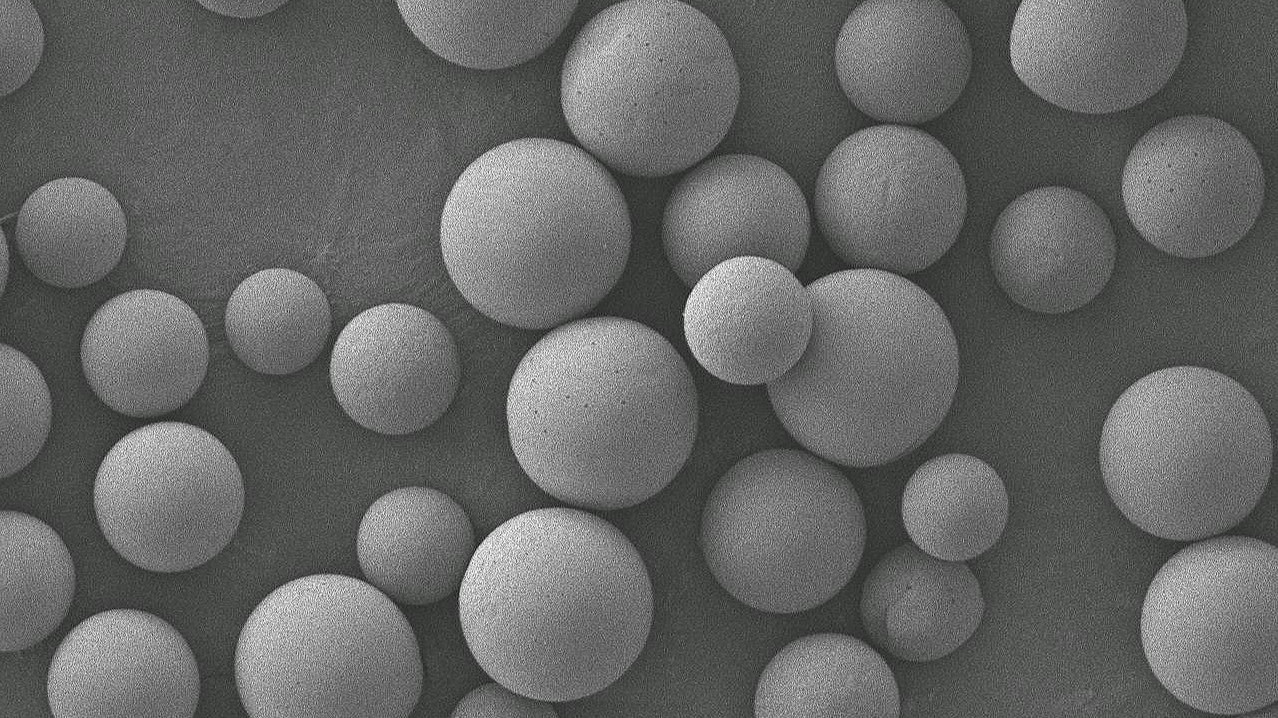

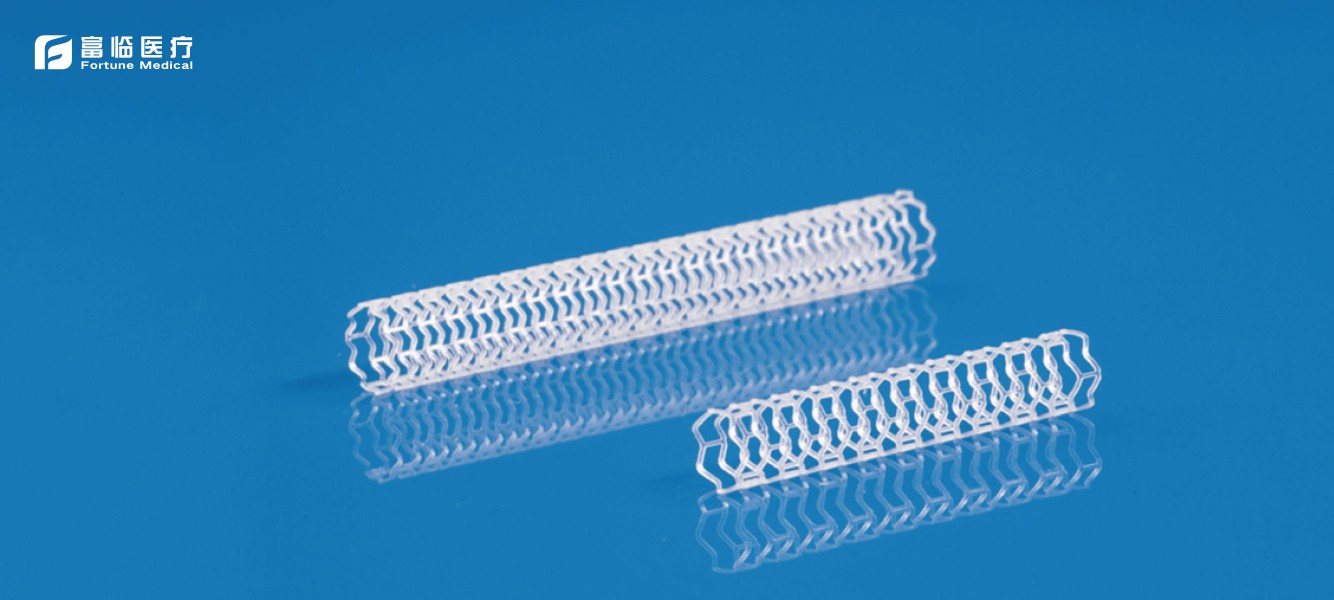

Dongguan Fortune Medical Technology Co., Ltd. is based on medical monomers and medical degradable polymer polyester materials (biomaterials), with interventional non-implantable devices (absorbable devices) as the core, providing customers with integrated, End-to-end high-end consumables R&D and production services continue to lower the R&D threshold for absorbable medical devices and help customers improve R&D efficiency. Bring more breakthrough treatment plans to patients, and the service scope covers the research and development and production of medical monomers, medical degradable polymer polyester materials (biomaterials), medical absorbable monofilaments/multifilaments, and absorbable medical devices.

In terms of polymer degradable materials and equipment, our technical core is based on years of accumulation, with mature and mature technical reserves, and has become a pioneer and leader in China's absorbable materials market.

Our website is online: "www.fortunemedical-int.com", and some pages are still under construction. Welcome to our official website to purchase products.

-

Quantitative Detection Method for Residual Monomer in Polylactic Acid

Polylactic acid has good biocompatibility and degradability, good thermoplasticity and high strength. It can be processed into various medical products. It has been widely used in medical device products such as fracture internal fixation and bone repair, degradable stents, absorbable sutures, tissue engineering stents, 3D printing implants, etc.2025-01-04

-

Application of biodegradable polymer materials in medical devices

The performance and degradation characteristics of several commonly used biodegradable polymer materials are reviewed, including polyglycolide,polylacticacid,(glycolide-lactide) copolymer,polycaprolactone,polydioxanone,polyhydroxyalkanoate, polytrimethylene carbonate, polyurethane and polyether urethane, etc., and their applications in medical devices, including implants, tissue engineering scaffolds, drug controlled release carriers, etc. are reviewed.2025-01-04

-

Method for determination of monomer residues in biodegradable polydioxanone materials

Establish a gas chromatography method for testing the residual monomer dioxanone in polydioxanone raw materials. A DB-624 capillary column (30.0 m ×535 μm ×3.00 μm) was used, and the temperature was programmed (146 ℃ for 5 min, 30 ℃/min to 200 ℃, and maintained for 2 min).2025-01-04