Objective: To establish a quantitative detection method for residual lactide monomer in polylactic acid using dichloromethane as solvent.

Method: Gas chromatography, solvent is dichloromethane, internal standard is 2,6-dimethyl-γ-pyrone, precipitant is acetone: cyclohexane = 3:16.

Result: In the range of 0.5~10.0 μg/ml, the peak area and concentration showed a good linear relationship (r²=0.9990), and the average recovery rate was 94.8%.

Conclusion: This method is accurate and reproducible, and can be used for the quantitative detection of residual monomer content in polylactic acid.

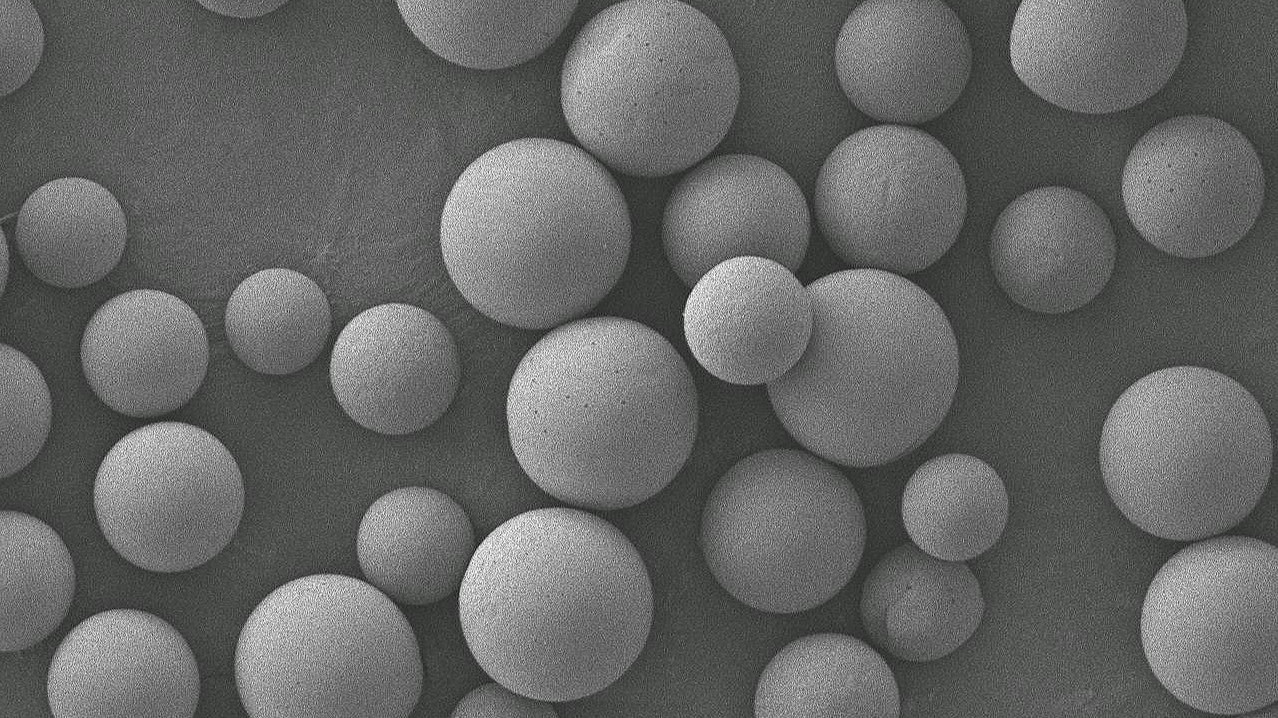

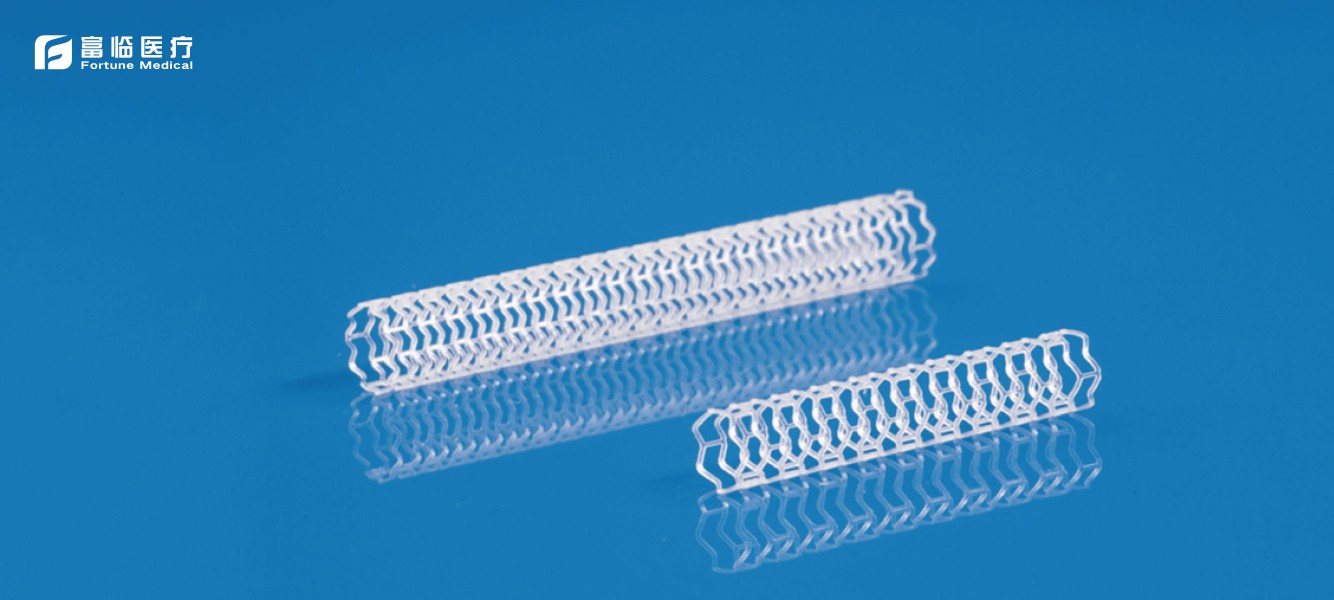

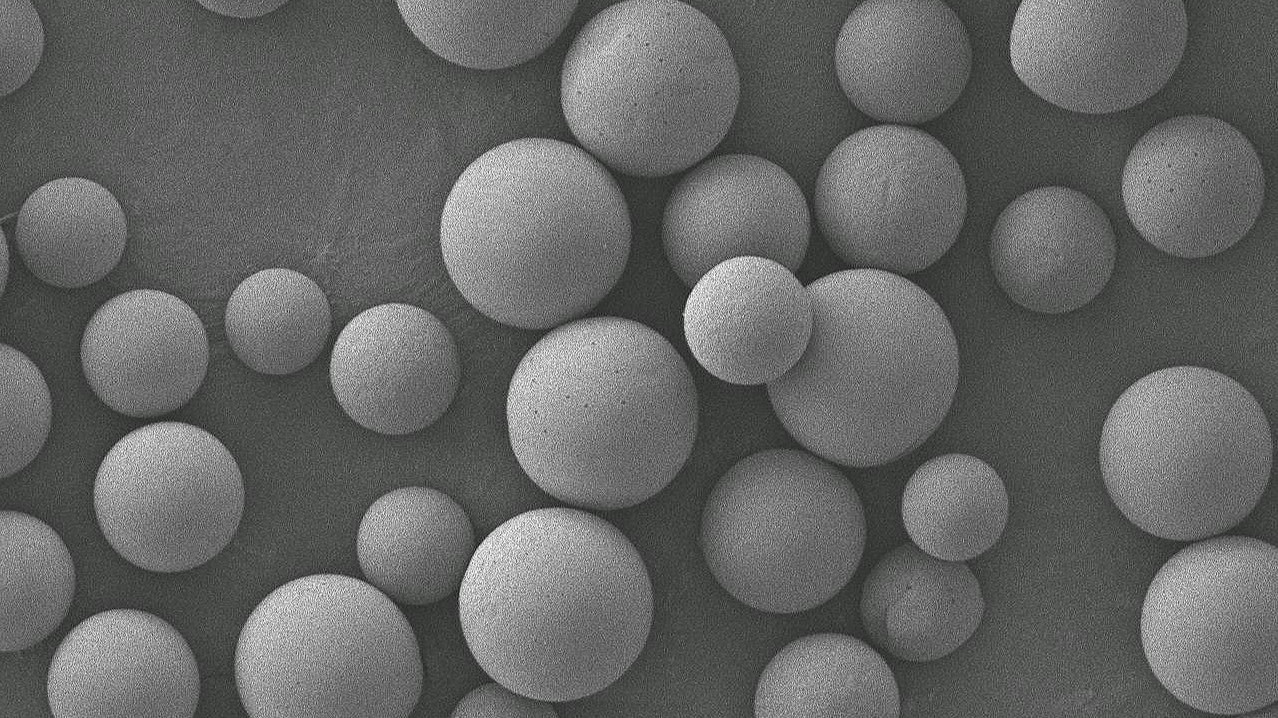

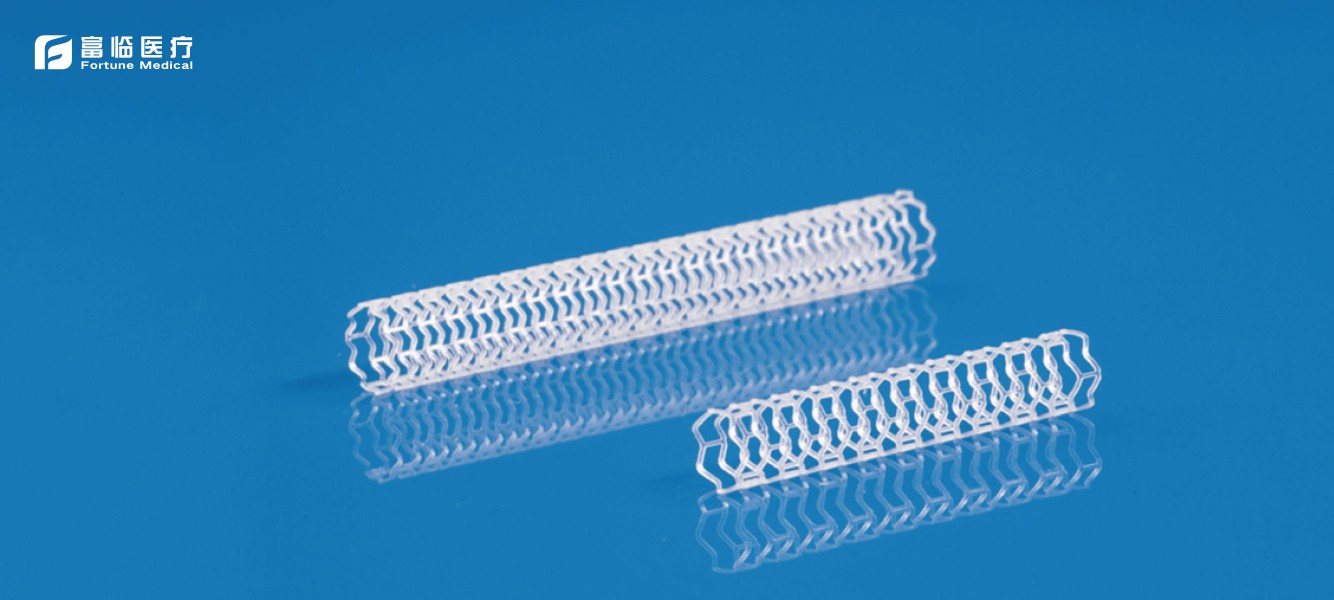

Polylactic acid has good biocompatibility and degradability, good thermoplasticity and high strength. It can be processed into various medical products. It has been widely used in medical device products such as fracture internal fixation and bone repair, degradable stents, absorbable sutures, tissue engineering stents, 3D printing implants, etc. The properties of polylactic acid are closely related to residual monomers, because the presence of monomers will not only cause a sharp drop in molecular weight and reduce performance, but also cause certain safety risks. The YY/T 0661-2017 standard has clear provisions on the limit of monomer residues, requiring no more than 2.0%. Therefore, accurate detection of monomer content is particularly important for the quality control of polylactic acid. At present, there are not many reports on the detection methods of residual lactide monomers in polylactic acid. The main methods are hydrogen nuclear magnetic resonance or gas chromatography with chloroform as solvent. Both methods have certain limitations. Hydrogen nuclear magnetic resonance cannot be quantitatively detected, and chloroform is highly toxic. Therefore, it is necessary to establish an accurate and practical quantitative detection method. In this study, dichloromethane was used as a solvent to dissolve the sample. After adding the internal standard, a precipitant was used to completely precipitate polylactic acid from the solution, while the internal standard substance and lactide monomer remained in the solution. After centrifugation, the supernatant was taken and tested using a gas chromatograph to eliminate the interference of polylactic acid degradation on the lactide content test.

I. Instruments and reagents

GC7890A, FID detector, DL-lactide reference substance, DL-polylactic acid sample, 2,6-dimethyl-γ-pyrone (TCI98.0%).

II. Methods and Results

2.1 Chromatographic Conditions

Chromatographic column HP-5 (30m×0.32mm×0.25μm); injection chamber temperature 240℃; detector temperature 300℃; column flow rate 1.0ml/min; injection volume 3μl; split ratio 10:1; tail gas 25 ml/min; hydrogen flow 40 ml/min; air flow 400 ml/min; column temperature, initial temperature 50℃, keep warm for 0 min, increase to 200℃ at 15℃/min, keep warm for 2 min, increase to 250℃ at 20℃/min, keep warm for 1.5 min.

2.2 Solution preparation

2.2.1 Test solution

Cool the sample to room temperature, accurately weigh 50 mg of the sample, put it into a 10 ml volumetric flask 1, add 2 ml of the internal standard solution with a concentration of 200 μg/ml, and then make up the volume with dichloromethane and shake well to ensure that the sample is completely dissolved; accurately measure 0.5 ml of the solution in volumetric flask 1 into a 10 ml volumetric flask 2, make up the volume with a mixture of acetone and cyclohexane, transfer the solution in volumetric flask 2 to a glass centrifuge tube, centrifuge at 1 000 rpm for 5 min, take a certain amount of supernatant with a syringe, filter it with a 0.22 μm organic filter head, and put it into the injection vial.

2.2.2 Reference solution

(1) Lactide stock solution: Place the lactide standard at room temperature for 2 h. When the temperature is constant, weigh 0.0502 g of the lactide standard into a 50 ml volumetric flask, dissolve and dilute with dichloromethane to obtain a lactide stock solution with a concentration of 1004 μg/ml. (2) Internal standard stock solution: Weigh 0.0104 g of 2,6-dimethyl-γ-pyrone internal standard into a 50 ml volumetric flask, dissolve and dilute with dichloromethane to obtain an internal standard stock solution with a concentration of 204 μg/ml. (3) Intermediate working solution: Accurately transfer different volumes from the lactide stock solution to each 10 ml volumetric flask 1 (see Table 2 for typical standard curve configuration steps), then add 2 ml of 204 μg/ml internal standard stock solution to each, dilute with dichloromethane to obtain a series of lactide intermediate working solutions. (4) Standard solution: Accurately pipette 0.5 ml of each of the lactide intermediate working solutions into a 10 ml volumetric flask 2, and then make up to volume with a mixture of acetone and cyclohexane. After mixing, a lactide standard curve solution with a concentration range of 0.5-10.0 μg/ml is obtained (Table 1).

Table 1. Preparation of standard solution.

2.3 Method suitability test

According to the given chromatographic conditions, 3 μl of blank solution, reference solution and test solution were taken respectively, and the chromatograms were recorded, as shown in Figure 1 (Figure 1A, Figure 1B, Figure 1C).

Figure 1. Gas chromatogram.

2.4 Linear relationship

Take the reference solution prepared by the method under "2.2.2" respectively, and measure it according to the given chromatographic conditions, record the chromatographic peak area of each concentration, and obtain the regression equation of Y=0.2757X0.0336 (r²=0.9990) by peak area (Y) versus solution concentration (X). In the range of 0.5~10.0 μg/ml, the peak area and concentration show a good linear relationship (Figure 2).

Figure 2. Gas phase standard curve.

2.5 Detection limit test

This test verifies that under this method, the standard solution of the test substance is diluted until the signal-to-noise ratio is ≥3, and the corresponding concentration at this time is the detection limit, see Table 2.

Table 2. Detection limit test results (n=6).

2.6 Quantitation limit test

This test verifies that under this method, the minimum amount of the test substance that can be quantitatively determined is the standard solution of the test substance. The standard solution is diluted until the signal-to-noise ratio is ≥10, and the corresponding concentration at this time is the quantitation limit, see Table 3.

Table 3. Quantitation limit test results (n=6).

2.7 Precision test

Take 6 samples of lactide for determination, prepare the test solution according to the method under "2.2.1", inject them separately, record the peak area and calculate the content, RSD=1.90% (n=6), see Table 4, indicating that the selected chromatographic conditions are systematically stable.

Table 4. Results of precision test (n=6).

2.8 Reproducibility test

Take the same sample for 6 repeated measurements, prepare the test solution according to the method under "2.2.1", inject the samples separately, record the peak area and calculate the content, RSD=1.17% (n=6), see Table 5, indicating that the method has good reproducibility.

Table 5. Results of repeatability test (n=6).

2.9 Recovery test

Take 3 samples with known content, add reference solution (2.008 μg/ml) to measure the peak area, calculate the recovery rate, the results are shown in Table 6, and the average recovery rate is 94.8%.

Table 6. Sample recovery test results (n=3).

2.10 Stability test

Accurately aspirate the 6 test sample solutions under "2.5" and inject them separately within 7 days according to the given chromatographic conditions. Record the peak area and calculate the content. RSD=0.78% (n=6), see Table 7, indicating that the sample solution is stable within 7 days.

Table 7. Stability test results (n=6).

III. Discussion

3.1 Selection of solvent

Polylactic acid can be dissolved in dichloromethane or chloroform, but because dichloromethane is relatively less toxic, dichloromethane is selected as the solvent.

3.2 Selection of precipitant

Poor solvents for polylactic acid can precipitate polylactide copolymer resin from the solution, while ensuring that the internal standard and lactide monomer are dissolved in the solution system. Cyclohexane, n-hexane, acetone or other suitable reagents can be selected.

3.3 Selection of internal standard

2,6-dimethyl-γ-pyrone has consistent physical and chemical properties with lactide monomer. Under chromatographic analysis conditions, the two have good separation and are not interfered by other components in the sample.

This study shows that the gas chromatography detection method is accurate, reproducible, and the results are stable.

Dongguan Fortune Medical Technology Co., Ltd. (Introduction to absorbable polymer materials)

Dongguan Fortune Medical Technology Co., Ltd. is based on medical monomers and medical degradable polymer polyester materials (biomaterials), with interventional non-implantable devices (absorbable devices) as the core, providing customers with integrated, End-to-end high-end consumables R&D and production services continue to lower the R&D threshold for absorbable medical devices and help customers improve R&D efficiency. Bring more breakthrough treatment plans to patients, and the service scope covers the research and development and production of medical monomers, medical degradable polymer polyester materials (biomaterials), medical absorbable monofilaments/multifilaments, and absorbable medical devices.

In terms of polymer degradable materials, our technical core is based on years of accumulation, and we have mature and proven technical reserves. We have become a pioneer and leader in the Chinese absorbable materials market.

-

Quantitative Detection Method for Residual Monomer in Polylactic Acid

Polylactic acid has good biocompatibility and degradability, good thermoplasticity and high strength. It can be processed into various medical products. It has been widely used in medical device products such as fracture internal fixation and bone repair, degradable stents, absorbable sutures, tissue engineering stents, 3D printing implants, etc.2025-01-04

-

Application of biodegradable polymer materials in medical devices

The performance and degradation characteristics of several commonly used biodegradable polymer materials are reviewed, including polyglycolide,polylacticacid,(glycolide-lactide) copolymer,polycaprolactone,polydioxanone,polyhydroxyalkanoate, polytrimethylene carbonate, polyurethane and polyether urethane, etc., and their applications in medical devices, including implants, tissue engineering scaffolds, drug controlled release carriers, etc. are reviewed.2025-01-04

-

Method for determination of monomer residues in biodegradable polydioxanone materials

Establish a gas chromatography method for testing the residual monomer dioxanone in polydioxanone raw materials. A DB-624 capillary column (30.0 m ×535 μm ×3.00 μm) was used, and the temperature was programmed (146 ℃ for 5 min, 30 ℃/min to 200 ℃, and maintained for 2 min).2025-01-04