SYYZ01000B Equipment Parameters

Equipment dimensions: 355mm * 380mm * 270mm

Equipment voltage: AC220V 50Hz

Equipment power: 520W

Equipment weight: 20Kg

Types of sewing threads applicable: PP thread, PDO, multi-strand thread, braided thread…

Shapes of sewing needles applicable: round needle, triangular needle

Diameter of suitable sewing needles: 0.35mm - 1.3mm

(Customized according to user requirements)

Pressing cycle: 1s/time

(There will be differences according to personal usage conditions)

Number of pressing times: adjustable (freely set according to requirements)

Is the pressing force adjustable: Yes

Is the pressing spacing adjustable: Yes

Product switching: replace the pressing mold

Types of pressing molds: customized according to user requirements

Other functions: equipped with production quantity counting, adjustable pressing speed and cycle, pre-pressing

Product Overview

The electric needle pressing machine is applied to the production of connecting the needle and thread of medical suture threads. It can press and connect the needle and thread perfectly, and is suitable for the needle pressing production of various types of suture threads (such as PP threads, PDO threads, multi-strand threads, braided threads, etc.). The equipment is easy to operate, runs stably, has high production capacity, and is equipped with a variety of flexible production functions, making it more suitable for various technological working conditions.

Product Features

·Suitable for multiple types of threads and needles It is suitable for PP threads, PDO threads, multi-strand threads, braided threads... etc. It is suitable for round needles and triangular needles. It is suitable for needle diameters ranging from 0.35 to 1.3mm (customization can also be made according to user requirements).

·Stable crimping process The equipment is purely electrically controlled, and its operation is smoother and more stable, which improves the yield rate of good products and the production output.

·Adjustable crimping force and clearance The crimping force can be freely adjusted according to the requirements of the usage process, and the crimping clearance of the crimping mold can be freely adjusted, which is compatible with a variety of thread and needle processes.

·Customizable editing of multiple flexible production functions It has functions such as production quantity counting, adjustable crimping times, adjustable crimping speed and cycle, pre-crimping, etc., and supports free editing and setting, making it more flexible to use and compatible with more working conditions.

·Operation mode It adopts a foot pedal switch activation mode. The human-machine interaction operation is simple, adapting to fast and efficient production operations.

Dongguan Fortune Medical Technology Co., Ltd. (Introduction to absorbable polymer materials)

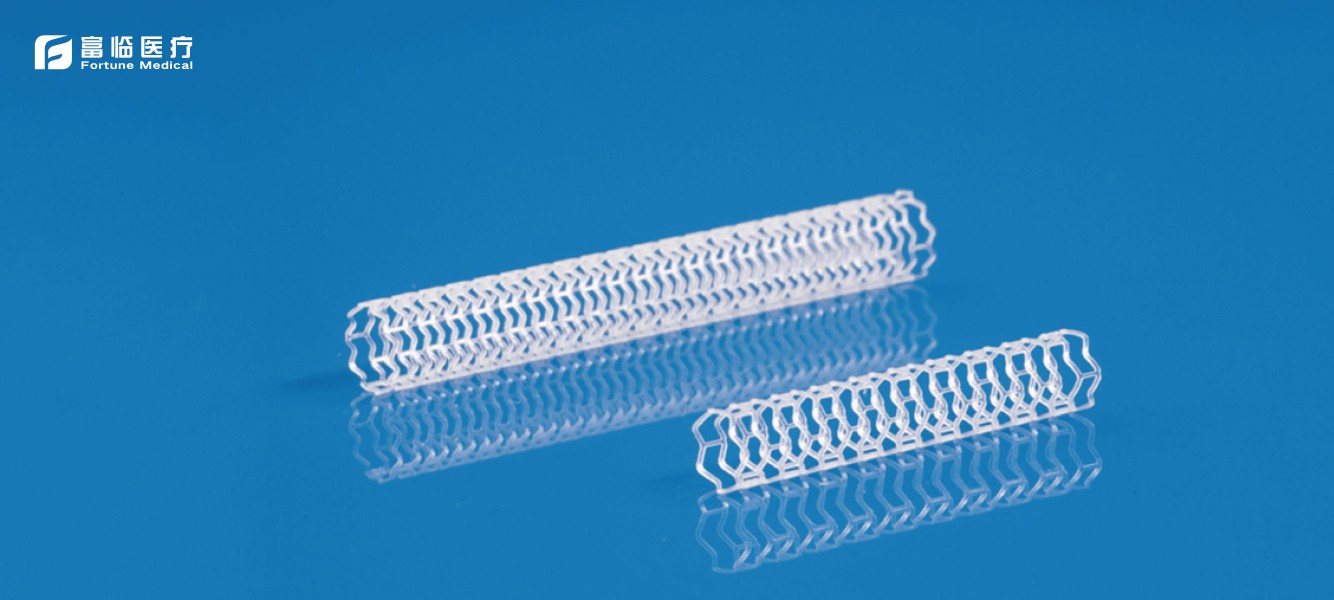

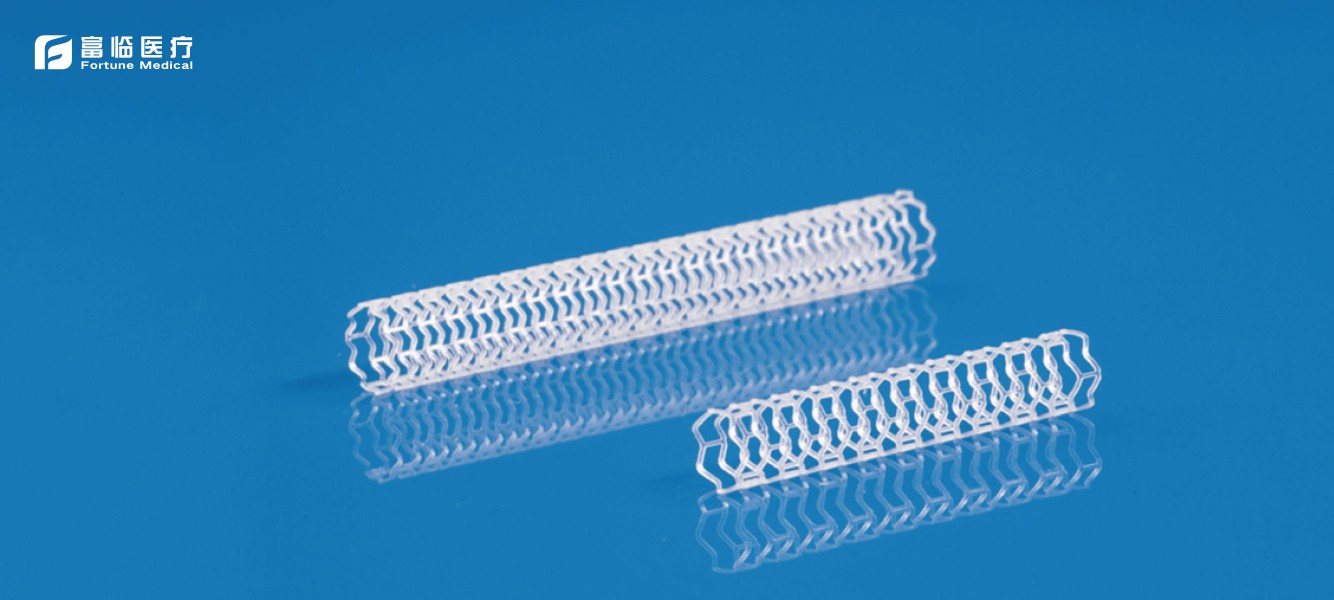

Dongguan Fortune Medical Technology Co., Ltd. is based on medical monomers and medical degradable polymer polyester materials (biomaterials), with interventional non-implantable devices (absorbable devices) as the core, providing customers with integrated, End-to-end high-end consumables R&D and production services continue to lower the R&D threshold for absorbable medical devices and help customers improve R&D efficiency. Bring more breakthrough treatment plans to patients, and the service scope covers the research and development and production of medical monomers, medical degradable polymer polyester materials (biomaterials), medical absorbable monofilaments/multifilaments, and absorbable medical devices.

In terms of polymer degradable materials and equipment, our technical core is based on years of accumulation, with mature and mature technical reserves, and has become a pioneer and leader in China's absorbable materials market.

Our website is online: "www.fortunemedical-int.com", and some pages are still under construction. Welcome to our official website to purchase products.

-

Quantitative Detection Method for Residual Monomer in Polylactic Acid

Polylactic acid has good biocompatibility and degradability, good thermoplasticity and high strength. It can be processed into various medical products. It has been widely used in medical device products such as fracture internal fixation and bone repair, degradable stents, absorbable sutures, tissue engineering stents, 3D printing implants, etc.2025-01-04

-

Application of biodegradable polymer materials in medical devices

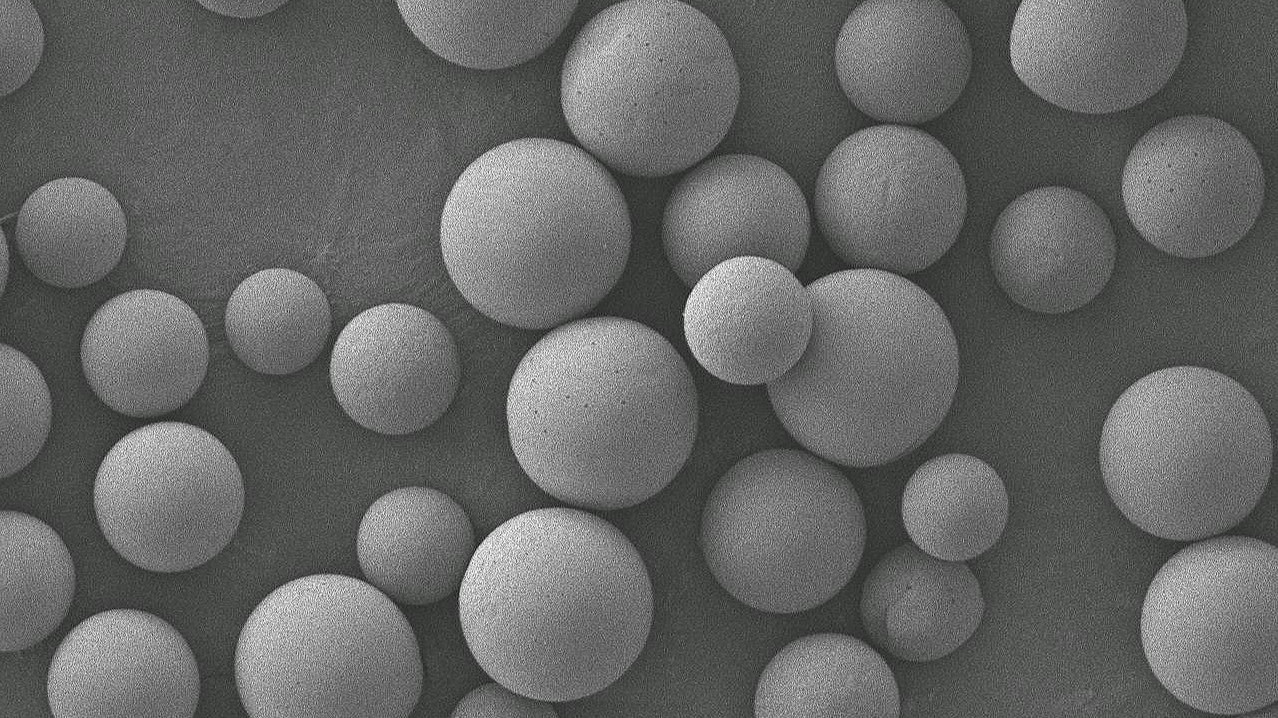

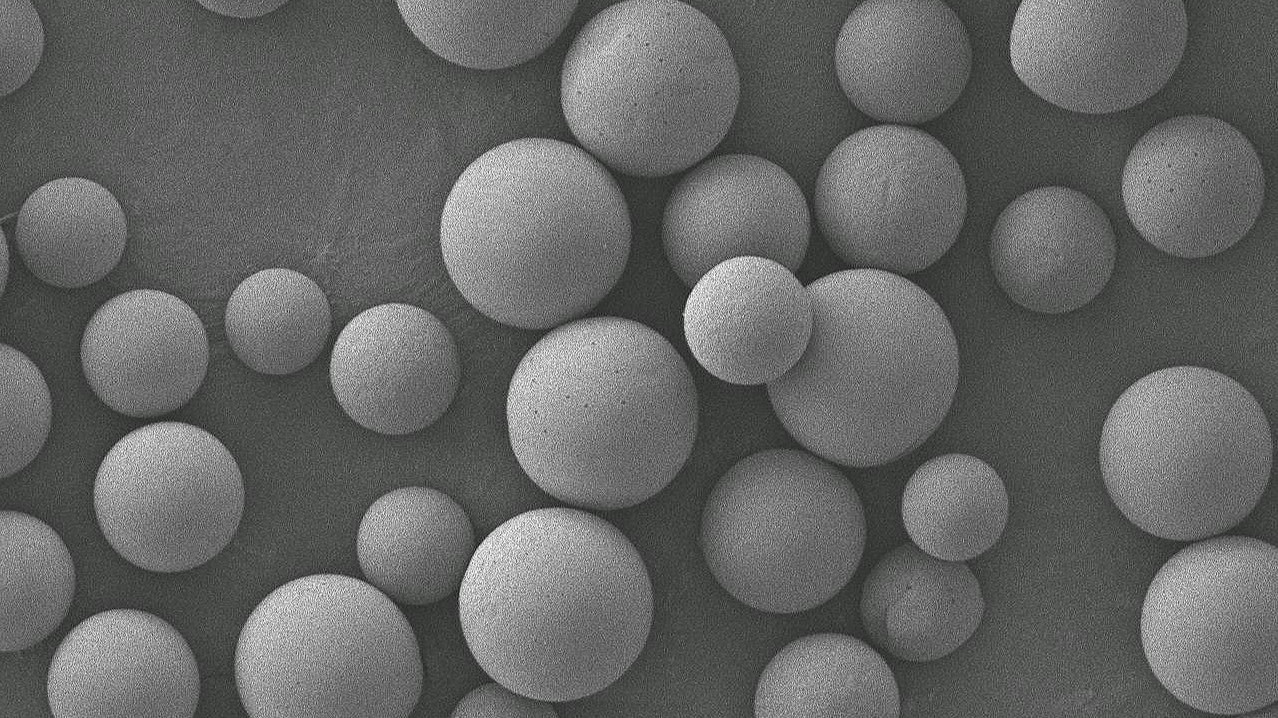

The performance and degradation characteristics of several commonly used biodegradable polymer materials are reviewed, including polyglycolide,polylacticacid,(glycolide-lactide) copolymer,polycaprolactone,polydioxanone,polyhydroxyalkanoate, polytrimethylene carbonate, polyurethane and polyether urethane, etc., and their applications in medical devices, including implants, tissue engineering scaffolds, drug controlled release carriers, etc. are reviewed.2025-01-04

-

Method for determination of monomer residues in biodegradable polydioxanone materials

Establish a gas chromatography method for testing the residual monomer dioxanone in polydioxanone raw materials. A DB-624 capillary column (30.0 m ×535 μm ×3.00 μm) was used, and the temperature was programmed (146 ℃ for 5 min, 30 ℃/min to 200 ℃, and maintained for 2 min).2025-01-04