Synthesis and Degradation Performance of PoIy(glycolic acid-co-caprolactone)

Poly( glycolic acid-co-caprolactone) (Px)were synthesized by polymerization of glyeolicacid with caprolactone using stannous octoate as the catalyst. In vitro accelerated degradation of Px were investigated. The results showed that the degradation process of Px can be divided into the following three stages: 0h ~12h, 12h~36h and 36h~72h. Px with high GA content exhibited faster degradation rate.

Polyglycolic acid (PGA) has better mechanical properties, but degradation in the external biological environment is too fast, resulting in a rapid loss of mechanical properties, which can not meet the requirements of high strength and slow degradation of medical materials in practice. The chain segment composed of lactone (CL) monomer has excellent crystallization properties and better hydrophobicity than GA chain segment.

In order to maintain the mechanical properties of PGA and delay its degradation time, so as to meet the different needs of its practical application as a medical material, this paper synthesized glycolide-caprolactone random copolymer (PX, Scheme 1) by polymerization reaction of glycolide (GA) and caprolactone (CL) catalyzed by stannous octoate, and investigated its accelerated degradation in vitro.

I. Experimental part

01. Instruments and reagents

CHP-9080 constant temperature water bath; PHS-25C acidity meter.

GA and CL, homemade; stannous octoate, analytical grade, Sigma Aldrich; hexafluoroisopropanol, analytical grade, DuPont; toluene and ether, analytical grade; all other reagents used were analytical grade.

02. Synthesis of Px

Add GA5.0g (43mmol), CL44.0g (387 mmol) and stannous octoate 15mg (0.037 mmol) toluene (0.3 mL) solution in a dry reaction bottle, evacuate, replace with nitrogen three times, and react at 150 ℃ for 36h under stirring. Cool to room temperature, dissolve with hexafluoroisopropanol (50 mL), add ether 25 mL (precipitate), filter, and vacuum dry the filter cake at 40℃ to constant weight to obtain P10 [x% = n (CL) / [n (CL) + n (GA)] x100% = 10%].

Change x and prepare Px (x = 20, 30, 40 and 50) by similar method.

03. In vitro degradation experiment

In order to shorten the in vitro degradation experiment cycle, the degradation temperature was appropriately increased in this paper. The degradation temperature of the accelerated degradation experiment should be higher than 37℃ and lower than the temperature range of polymer melting or softening. The accelerated degradation of Px was studied at (70±1)℃ to investigate its mass loss, water absorption rate and pH value change during the degradation process.

PGA and Px were completely immersed in PBS buffer solution (pH=7.40) prepared with Na2HPO4 and KH2PO4, and placed in a constant temperature water bath (70℃) for in vitro degradation experiments. Samples were taken every 12 hours for testing.

(1) Water absorption rate and mass loss

The mass of the sample before degradation was W0. It was washed three times in deionized water at different time points. The surface water was absorbed with filter paper and weighed as W1. After vacuum drying to constant weight, it was weighed as W2. The water absorption rate and mass loss rate were calculated according to the following formula.

(2) pH change

The effect of sample degradation on the pH of the degradation solution was investigated. The degradation solution was not replaced. At the predetermined degradation time, samples were directly taken to detect its pH value.

II. Results and discussion

01. In vitro accelerated degradation performance

(1) Mass loss rate and water absorption rate

Figure 1 shows the mass changes of PGA and Px during the degradation process in PBS (pH=7.40, 70℃) solution. As shown in Figure 1, in the first 12h of degradation, the mass loss of PGA and Px is comparable; in the 12h~36h stage, the mass loss of PGA is the fastest, and as the GA content in Px decreases, its mass loss rate also decreases; in the 36h~72h stage, except for P40, the change pattern of the remaining Px is opposite to that of the second stage, that is, the mass loss rate of PGA slows down, and the less GA content in Px, the faster its mass loss. Only P40 maintains the loss rate of the second stage, and its final mass loss is comparable to that of PGA. The above change pattern is mainly related to the different monomer structures in the polymer and its hydrophilic and hydrophobic properties. The crystallization performance of Px mainly comes from the GA segment, and the GA monomer structure has better hydrophilic properties than the CL monomer. Therefore, in the first 36 hours of degradation, the degradation of Px is mainly due to the hydrolysis and chain scission of the molecular chain segments due to water absorption. Therefore, PGA with better hydrophilicity and Px with more GA content degrade faster, which is manifested as a greater mass loss rate; because the crystal region of the polymer has a compact texture, it can delay the invasion of water, so the degradation of high-crystallinity polymers is delayed. 36 hours after degradation, due to the regular arrangement of GA segments, its crystallinity is better, so the degradation of PGA and Px with more GA content is delayed.

Figure 1. Mass changes of PGA and Px during degradation in PBS

pH=7.40,70℃

Figure 2 shows the changes in water absorption during the degradation of PGA and Px in PBS (pH=7.40, 70°C). As can be seen from Figure 2, the changes in water absorption of the three polymers with higher GA content (PGA, P10 and P20) are consistent. In the first 12 hours of degradation, the polymer molecular chain undergoes hydrolysis and chain scission, and a small amount of water molecules enter the polymer structure; in the degradation stage of 12h~36h, a large number of ester bonds are hydrolyzed, causing a large number of water molecules to enter the internal structure of the polymer, and its water absorption rate increases rapidly; in the degradation stage of 36h~72h, due to the increase in the crystallization performance of the small molecular chain segments in the polymer, the invasion of water molecules is hindered to a certain extent, which slows down the water absorption rate of the material. However, the changes in water absorption of the two polymers with lower GA content (P30 and P40) are quite special. Among them, P40 itself has a certain elasticity, its crystallization performance is also poor, and the internal structure of the material is relatively loose. Therefore, in the initial stage of degradation, it shows a large water absorption rate. In the later stage of degradation, its water absorption rate change is mainly affected by the hydrolysis of ester bonds, and there is a slight increase. In the middle and late stages of degradation, the water absorption rate of P30 is significantly lower than that of other polymers. It may be because this monomer ratio makes the hydrophilicity and crystallization performance of the material reach a better ratio, so that its water absorption rate during the degradation process is relatively small.

Figure 2. Changes in water absorption during the degradation of PGA and Px in PBS

pH=7.40,70℃

(2) pH value

The hydrolysis rate of biodegradable materials depends on the pH change of the environment. In this degradation experiment, a weakly alkaline PBS buffer solution (pH=7.40, 70 ℃) was selected as the in vitro degradation environment. Figure 3 shows the pH change of PGA and Px during the degradation process in PBS. As can be seen from Figure 3, the pH values of PGA and Px decreased with the extension of degradation time, but the degree and law of pH value decrease of polymers with different monomer ratios were inconsistent. In the first 12 hours of degradation, the pH value of all polymers changed consistently, which was consistent with the change in mass loss, because in the early stage of degradation, only the long chain segments were hydrolyzed, mainly the hydrolysis of the ester bonds in the GA segment, and the pH value of the aqueous solution had a certain delay, so the pH value decrease was relatively low. In the 12h~48h stage of degradation, the pH value of the degradation solution decreased sharply. As the GA content in the polymer increased, the pH value of the degradation solution decreased faster. During the 48h~72h degradation period, the pH value of the degradation solution of polymers with higher GA content (PGA, P10 and P20) basically did not change, while the pH value of the degradation solution of polymers with lower GA content (P30 and P40) only slowed down the rate of decrease. During this degradation period, the pH value continued to decrease. The pH values of PCA and Px at the end of degradation were basically the same. The change in pH value of the degradation solution is mainly because as the polymer degradation proceeds, the ester bond on the polymer chain is hydrolyzed, which causes the end carboxyl content in the degradation solution to increase continuously, causing the acidity to change; at the same time, the lower pH value accelerates the hydrolysis of the ester bond, resulting in autocatalysis. The pH value of polymers with higher GA content decreases faster because one GA monomer can form two glycolic acid molecules after degradation, which increases the proportion of end hydroxyl groups faster, so the pH value of PGA decreases fastest during the degradation process.

Figure 3. pH changes during the degradation of PGA and Px in PBS

pH=7.40,70℃

Dongguan Fortune Medical Technology Co., Ltd. (Introduction to absorbable polymer materials)

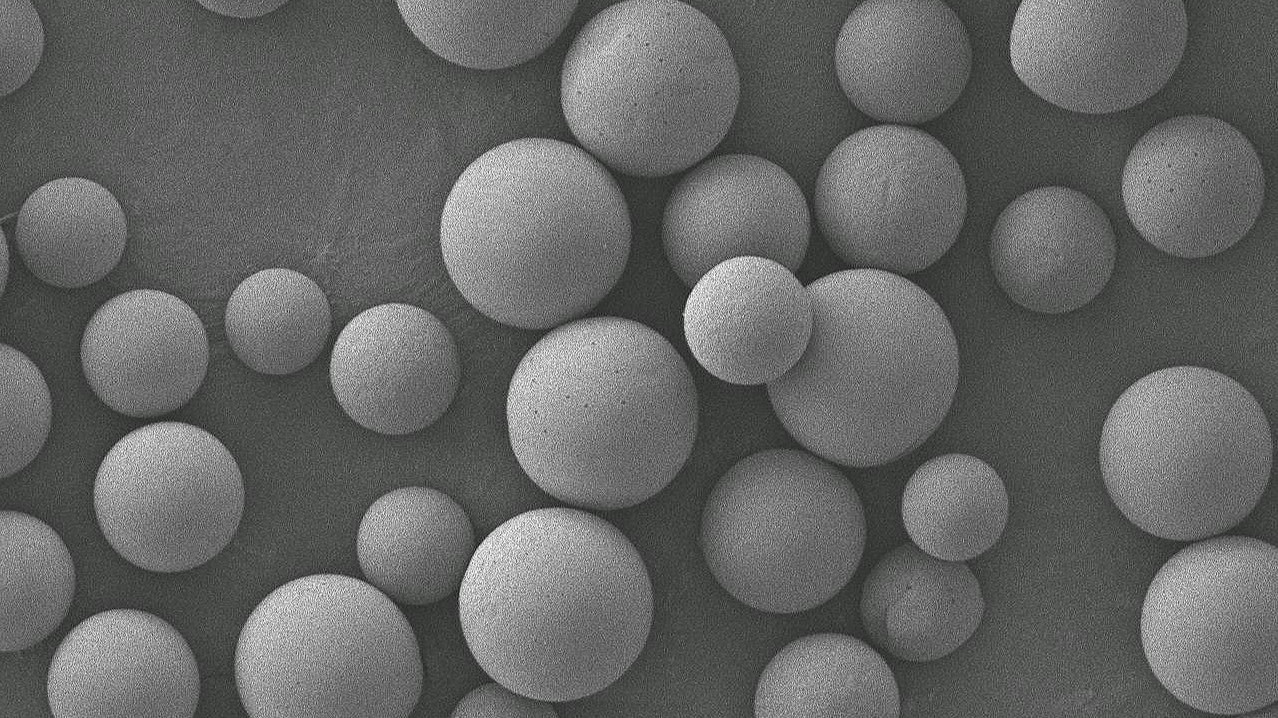

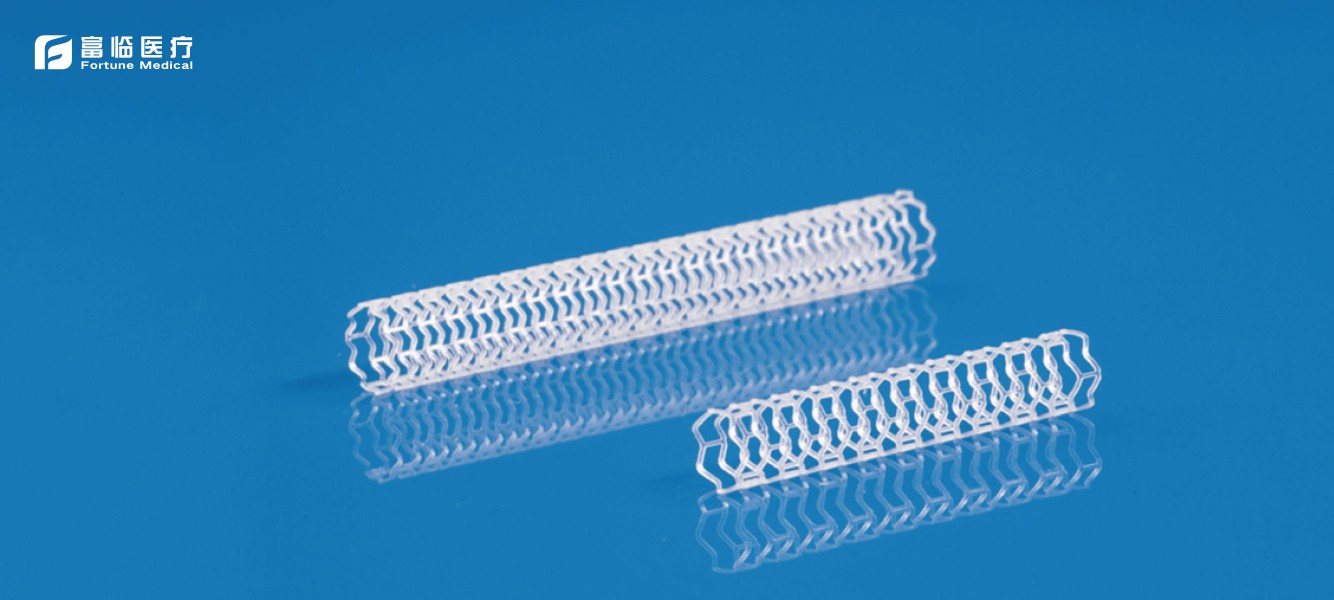

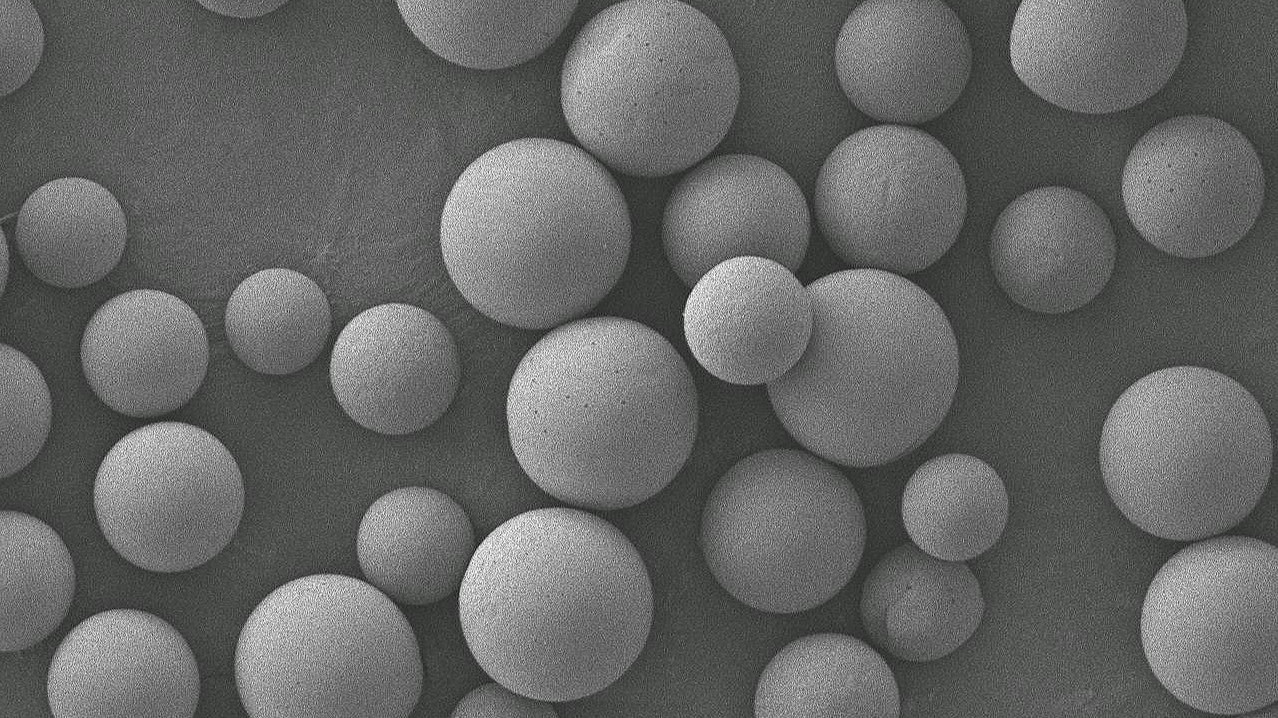

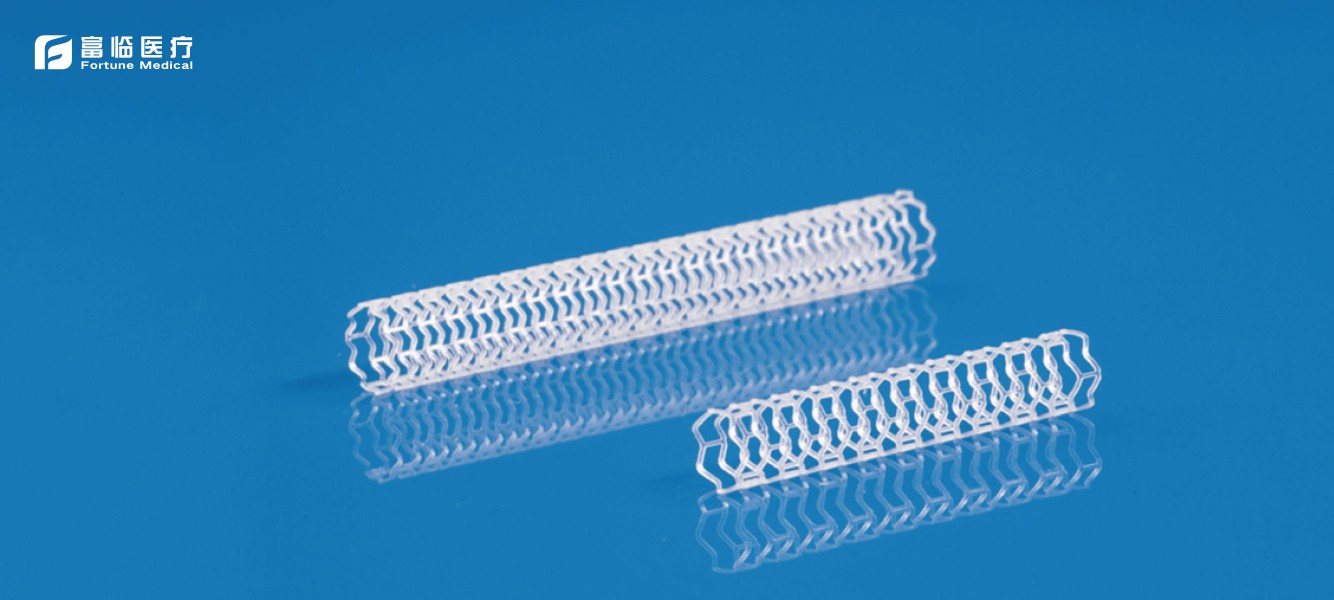

Dongguan Fortune Medical Technology Co., Ltd. is based on medical monomers and medical degradable polymer polyester materials (biomaterials), with interventional non-implantable devices (absorbable devices) as the core, providing customers with integrated, End-to-end high-end consumables R&D and production services continue to lower the R&D threshold for absorbable medical devices and help customers improve R&D efficiency. Bring more breakthrough treatment plans to patients, and the service scope covers the research and development and production of medical monomers, medical degradable polymer polyester materials (biomaterials), medical absorbable monofilaments/multifilaments, and absorbable medical devices.

In terms of polymer degradable materials, our technical core is based on years of accumulation, and we have mature and proven technical reserves. We have become a pioneer and leader in the Chinese absorbable materials market.

-

Quantitative Detection Method for Residual Monomer in Polylactic Acid

Polylactic acid has good biocompatibility and degradability, good thermoplasticity and high strength. It can be processed into various medical products. It has been widely used in medical device products such as fracture internal fixation and bone repair, degradable stents, absorbable sutures, tissue engineering stents, 3D printing implants, etc.2025-01-04

-

Application of biodegradable polymer materials in medical devices

The performance and degradation characteristics of several commonly used biodegradable polymer materials are reviewed, including polyglycolide,polylacticacid,(glycolide-lactide) copolymer,polycaprolactone,polydioxanone,polyhydroxyalkanoate, polytrimethylene carbonate, polyurethane and polyether urethane, etc., and their applications in medical devices, including implants, tissue engineering scaffolds, drug controlled release carriers, etc. are reviewed.2025-01-04

-

Method for determination of monomer residues in biodegradable polydioxanone materials

Establish a gas chromatography method for testing the residual monomer dioxanone in polydioxanone raw materials. A DB-624 capillary column (30.0 m ×535 μm ×3.00 μm) was used, and the temperature was programmed (146 ℃ for 5 min, 30 ℃/min to 200 ℃, and maintained for 2 min).2025-01-04