The in vitro degradation of Poly(para-dioxanone)with different mediums was studied by the changes of weight retention, water absorption,viscosity,pH value and mechanicalproperties of PPDO samples were examined in distilled water ( H2O) ( pH 60.50)、normal saline(NS (pH 4.50)and phosphate buffered saline(PBS) ( pH 7.44) at 37℃ for 4 weeks. The results suggested that the PPDO samples in H2O and NS exhibited faster degradation rate in vitro degradation.

Poly (p-dioxanone, PPDO) is a biodegradable polymer material with excellent performance. Due to the special chemical structure of PPDO, it has excellent hydrolysis and excellent biodegradability, biocompatibility, bioabsorbability, as well as excellent flexibility, tensile strength, and knotting strength. It has been approved by the US FDA as a medical absorbable surgical suture material. With the reduction of its production cost, PPDO is expected to become a general plastic to expand its application field. As an environmentally friendly material, the advantage of PPDO's degradability can be brought into play to reduce the damage of white pollution to the environment. In order to simulate the degradation process of PPDO in nature, we first selected different degradation media to study the degradation behavior of PPDO. The PPDO samples were immersed in distilled water (H2O), normal saline (NS), and buffer solution (PBS) for degradation experiments. The mass loss, water absorption, intrinsic viscosity and pH value changes in different media were investigated, and the trend of changes in the mechanical properties of PPDO was also investigated.

I. Experimental part

01. Instruments and reagents

Thermostatic water bath, acidity meter, electronic balance, electronic universal tester, homemade polydioxanone, homemade distilled water, physiological saline, Na2HPO4 and KH2PO4. Hexafluoroisopropanol.

02. Sample preparation

Polydioxanone (PPDO) was synthesized in the laboratory with an intrinsic viscosity of 1.8. It was hot-pressed for 5 min at 140℃ and 5.5Mpa using a stainless steel mold to make a 0.5 mm thick sheet. The PPDO sheet was prepared and the sheet was processed into a strip of 50mm × 5mm × 0.5mm.

03. In vitro degradation experiment

The PPDO sample strips were divided into 5 groups, each with 3 parallel samples. The 4 groups of samples except the 0th week were immersed in PBS buffer solution (pH= 7.44), distilled water (pH = 6.50) and saline (pH = 4.50) prepared with Na2HPO4 and KH2PO4 in a 37℃ constant temperature water bath for in vitro degradation experiments. Samples were taken regularly every week for testing.

04. Water absorption and mass loss

The mass of the sample before degradation is Wo. The degraded sample is taken out at different time points, washed in deionized water for 3 times, and then the surface moisture is absorbed with filter paper, weighed W1, and then vacuum dried to constant weight, weighed W2. The water absorption of the sample is calculated using the following formula:

The mass loss of the sample is calculated using the following formula:

05. pH change

When investigating the effect of the degradation process on the pH of the degradation solution, the degradation solution is not replaced until the predetermined degradation time, and its pH value is directly detected. The pH value is measured using an acidometer.

06. Mechanical properties analysis

The mechanical properties test is carried out using an electronic universal testing machine, and the test content includes the tensile strength of the sample strips (3 parallel samples per group). The test temperature is 25℃ and the loading speed is 10.00 mm/min.

07. Determination of intrinsic viscosity

Hexafluoroisopropanol was used as solvent with a concentration of 0.1dL/g, and was measured by Ubbelohde viscometer in a constant temperature water bath at 25±0.1℃.

II. Results and discussion

01. In vitro degradation of samples

We used buffer solution with pH 7.44, distilled water with pH 6.50, and saline with pH 4.50 as decomposition media, and conducted hydrolysis tests on PPDO samples at 37℃ in water to investigate the effects of different media on the in vitro degradation behavior of PPDO. During the entire in vitro degradation experiment, the mass loss and water absorption rate of the samples gradually increased with the increase of degradation time, and the pH value gradually decreased, which was consistent with the in vitro degradation trend of PPDO composite materials we had previously conducted, but due to the change of hydrolysis media, its degradation behavior changed significantly.

Tables 1 and 2 are the in vitro degradation tests of PPDO samples under different environments, and the changes in their weight loss and water absorption rate. Table 3 is the changes in the acidity of PPDO samples in PBS, NS and H2O at different time points.

Table 1. Weight loss of PPDO samples in different mediums with degradation time.

Table 2. Water absorption of PPDO samples in different mediums with degradation time.

Table 3. pH value of PPDO samples in different mediums with degradation time.

Due to the presence of ester bonds and ether bonds in the PPDO molecular chain, it has good hydrophilicity and a short degradation time. In the PBS buffer solution, significant hydrolysis has begun to occur within 8 weeks of degradation, and its mass loss rate and water absorption rate have increased significantly at 8 weeks, which has been reported in our previous work. We first selected distilled water and physiological saline as the degradation medium of PPDO in order to investigate the changing trend of the degradation behavior of PPDO as a general plastic in different environments and to study the relationship between its degradation behavior and the medium in which it is located.

From Table 1 and Table 2, we can find that no matter what kind of degradation medium PPDO is in, the general law of its degradation behavior is the same: the mass loss rate and water absorption rate both increase gradually with the extension of degradation time. However, there are huge differences in the degradation rate, especially in terms of mass loss rate. In PBS buffer solution, PPDO is only 1.52% in the 4th week, while the mass loss rates of PPDO in distilled water and saline are 5.06% and 4.18%, respectively, which are 333% and 275% of the degradation rate of PBS buffer in the same period, indicating that its degradation rate has increased significantly. It is also worth noting that the mass loss rate of PPDO in PBS buffer increased relatively slowly in the first 4 weeks, from 1.03% to 1.52%, an increase of 47.57%, while the corresponding values of distilled water and saline are 450% and 345%, respectively, and the increase is very large. The reason is mainly caused by the acidity of the different media in which PPDO is located. Due to the low initial pH value of distilled water and saline, the autocatalytic effect is significantly enhanced due to the increase in acidity, which accelerates the hydrolysis and cleavage of the ester bond, and at the same time causes the sample to accelerate degradation into small fragments, which can be dissolved in the degradation solution. The direct result is an increase in mass loss rate. The mass loss rate of PPDO sample in PBS buffer was only 3.94% at the 8th week, which is comparable to the level of PPDO in distilled water or saline at the 3rd-4th week. This shows that the degradation rate of PPDO in distilled water and saline is about 1 times that in PBS buffer solution.

As shown in Table 2, similar to the mass loss, the water absorption rate of PPDO also showed a single linear change during the in vitro degradation process. When the degradation test was carried out to the 4th week, the water absorption rate of PPDO in PBS buffer, saline and distilled water increased to 5.47%, 7.65% and 7.89% respectively. Similarly, the water absorption rate of PPDO in distilled water and saline was greater than that in PBS buffer solution. This phenomenon was also attributed to the increase in the acidity of the medium in which PPDO was located, which led to the acceleration of degradation and the penetration of water molecules into the interior of PPDO. At the same time, the water absorption rate of the sample also depends on the fine cracks formed on its surface. As the in vitro degradation of the PPDO sample progresses, more defects are formed on its surface, and its water absorption rate gradually increases.

The change of pH value of degradation buffer also follows a similar rule. The acidity of the medium in which PPDO is located is gradually decreasing, but the difference is also obvious. The pH value of PBS buffer is 7.31 at the 4th week, while that of distilled water and saline is 2.28 and 2.18 respectively at the 4th week. This is due to two reasons. On the one hand, the initial pH value of distilled water and saline is low. On the other hand, this acidic medium leads to the accelerated degradation of PPDO samples, and its acidic products are further increased. The synergistic effect of these two leads to a significant decrease in the pH value of distilled water and saline.

As can be seen from Table 4, the intrinsic viscosity of PPDO samples has been in a downward trend with the extension of degradation time, and this trend is very obvious. However, the molecular weight of PPDO samples in physiological saline and distilled water decreases much more than that in buffer solution. In the first week, PPDO samples still maintain a high viscosity in buffer solution, while in the other two media, the molecular weight of PPDO decreases more, both by more than 50%, indicating that the degradation rate of PPDO samples in physiological saline and distilled water is much greater than that in buffer solution.

Table 4. Viscosity of PPDO samples in different mediums with degradation time.

02. Analysis of sample mechanical properties

PPDO samples were degraded in PBS buffer. As time went on, the tensile strength changed due to the increase in crystallinity, the decrease in molecular weight and the surface defects of the samples. In the first two weeks of degradation, the tensile strength showed a slight increase, which was mainly due to the increase in crystallinity. At this stage, the increase in crystallinity was the main reason affecting the tensile strength. The mechanical strength of PPDO samples in distilled water and saline decreased sharply, which was mainly caused by the surface defects of the samples, corresponding to the increase in mass loss rate and water absorption rate. It can also be seen from Figure 1 that after 4 weeks of degradation in the finishing water, the morphology of the PPDO samples changed dramatically, and they were all broken and shattered, and the mechanical properties completely disappeared.

Table 5. Tensile strength of PPDO samples in different mediums with degradation time.

Fig.1. Morphology image of PPDO samples in H20 with degradation time.

III. Conclusion

From the above research results, we know that the degradation rate of PPDO samples in distilled water and physiological saline is significantly increased, which is about 1 times higher than that in PBS buffer. We simulated the degradation behavior of PPDO in pure water and physiological saline for the first time, which has a very positive guiding significance in expanding PPDO as a general plastic and its application in a wider range of fields.

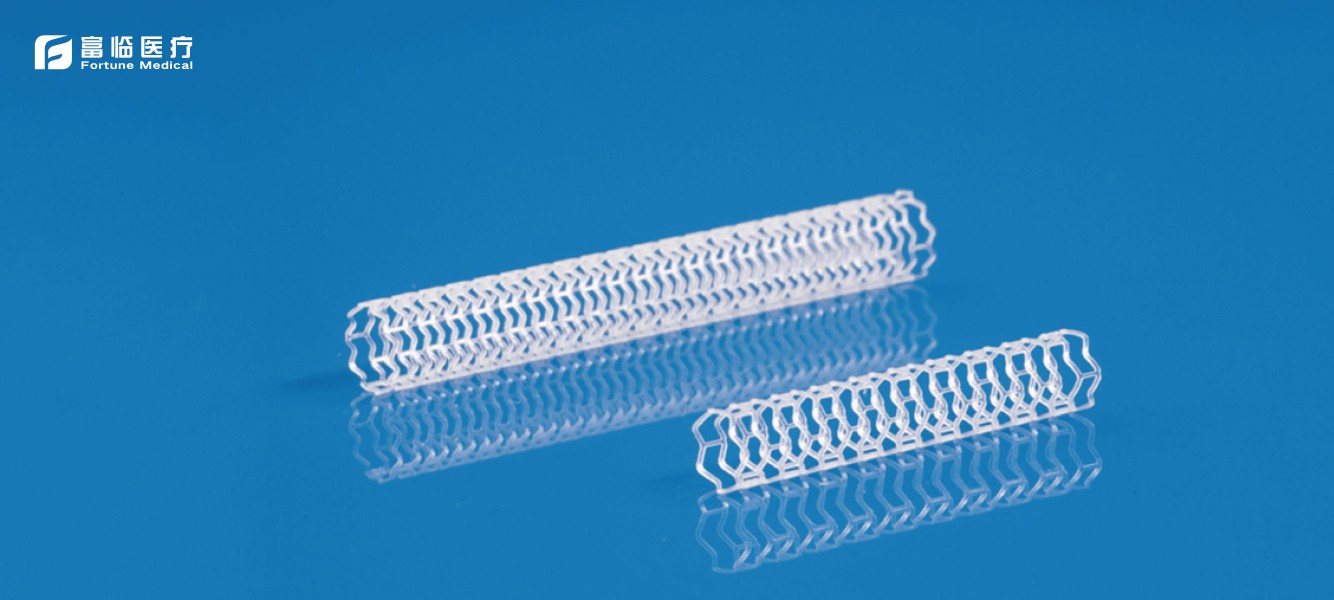

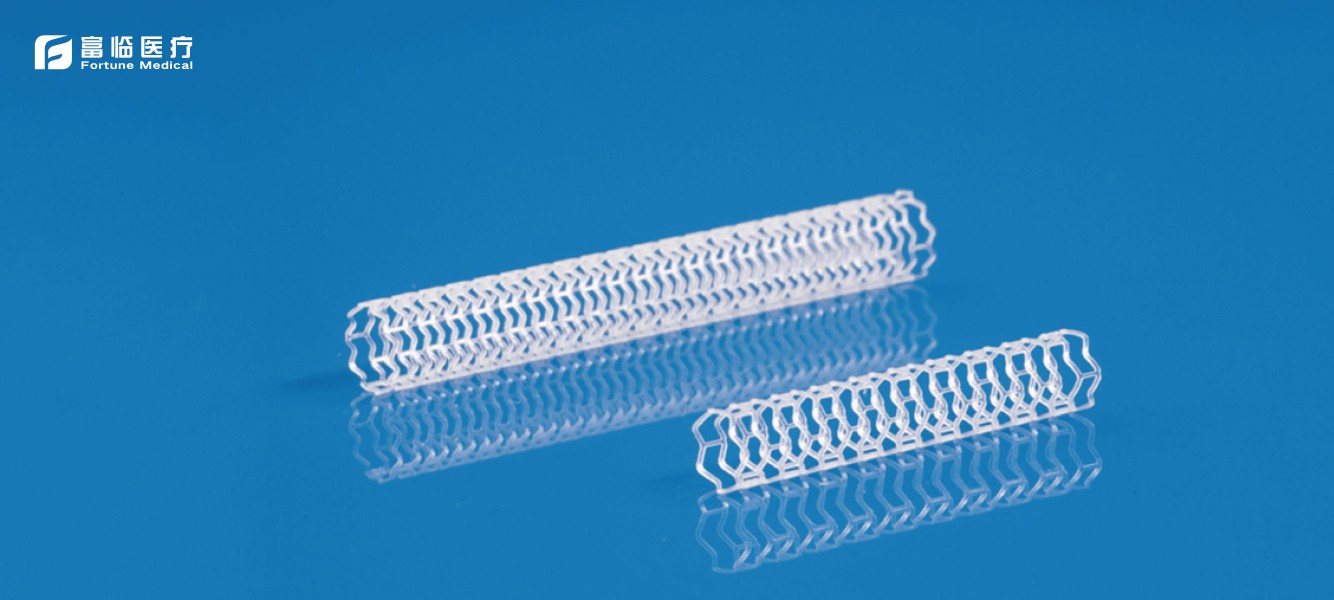

Dongguan Fortune Medical Technology Co., Ltd. (Introduction to absorbable polymer materials)

Dongguan Fortune Medical Technology Co., Ltd. is based on medical monomers and medical degradable polymer polyester materials (biomaterials), with interventional non-implantable devices (absorbable devices) as the core, providing customers with integrated, End-to-end high-end consumables R&D and production services continue to lower the R&D threshold for absorbable medical devices and help customers improve R&D efficiency. Bring more breakthrough treatment plans to patients, and the service scope covers the research and development and production of medical monomers, medical degradable polymer polyester materials (biomaterials), medical absorbable monofilaments/multifilaments, and absorbable medical devices.

In terms of polymer degradable materials, our technical core is based on years of accumulation, and we have mature and proven technical reserves. We have become a pioneer and leader in the Chinese absorbable materials market.

-

Quantitative Detection Method for Residual Monomer in Polylactic Acid

Polylactic acid has good biocompatibility and degradability, good thermoplasticity and high strength. It can be processed into various medical products. It has been widely used in medical device products such as fracture internal fixation and bone repair, degradable stents, absorbable sutures, tissue engineering stents, 3D printing implants, etc.2025-01-04

-

Application of biodegradable polymer materials in medical devices

The performance and degradation characteristics of several commonly used biodegradable polymer materials are reviewed, including polyglycolide,polylacticacid,(glycolide-lactide) copolymer,polycaprolactone,polydioxanone,polyhydroxyalkanoate, polytrimethylene carbonate, polyurethane and polyether urethane, etc., and their applications in medical devices, including implants, tissue engineering scaffolds, drug controlled release carriers, etc. are reviewed.2025-01-04

-

Method for determination of monomer residues in biodegradable polydioxanone materials

Establish a gas chromatography method for testing the residual monomer dioxanone in polydioxanone raw materials. A DB-624 capillary column (30.0 m ×535 μm ×3.00 μm) was used, and the temperature was programmed (146 ℃ for 5 min, 30 ℃/min to 200 ℃, and maintained for 2 min).2025-01-04