A headspace gas chromatography method was established for the determination of residual solvents in poly( lactide - co-glycolide) . The method was programmed with DB - 624 capillary column (30m x530μm x3.0μm) and fame ionization detector (FlD). The reults showed that the standard curves were linear in the range of expermental concentration, the average recoveries for four residual solvents were between 98.54% and 99.50% , the RSDs of precision was all less than 2% , the quantitation limits were 0.16 ug/ml ~ 1.17 mg/ml. The method is rapid, sensitive and accurate. It can be used for the determination of ethanol, acetone, dichloromethane and acetic ether in poly(lactide - co - glycolide) at the same time.

I. Introduction

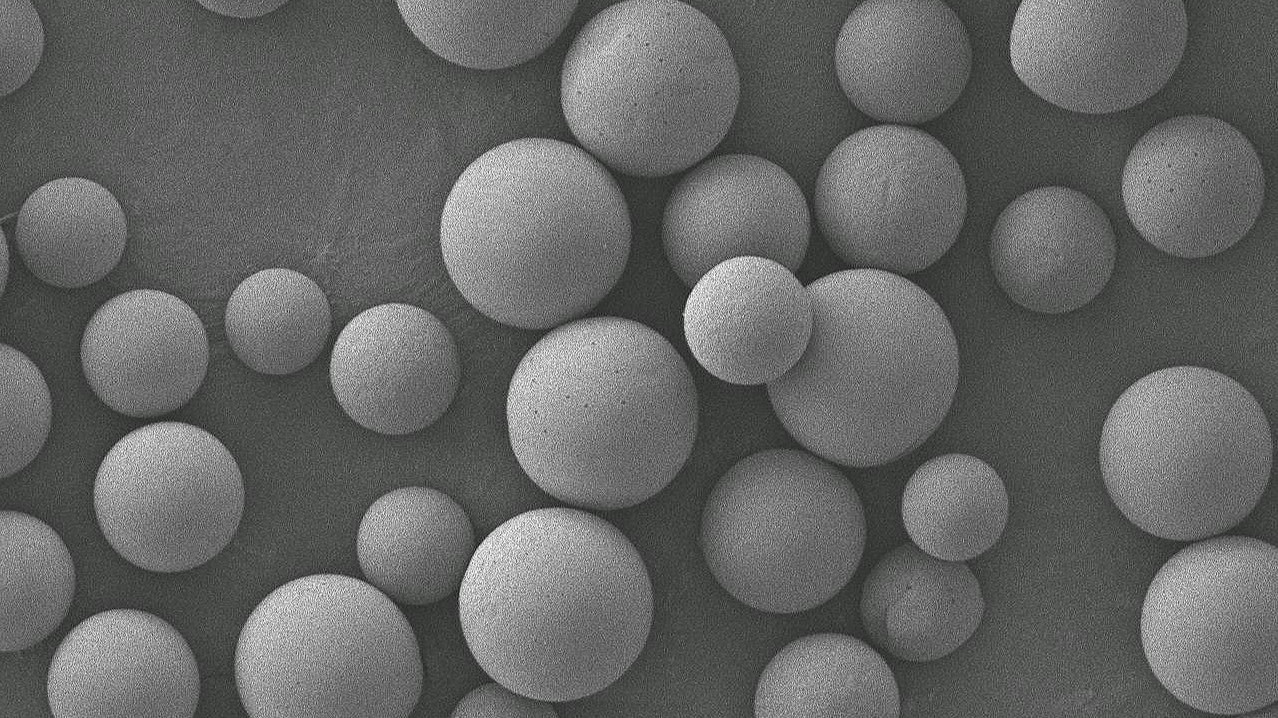

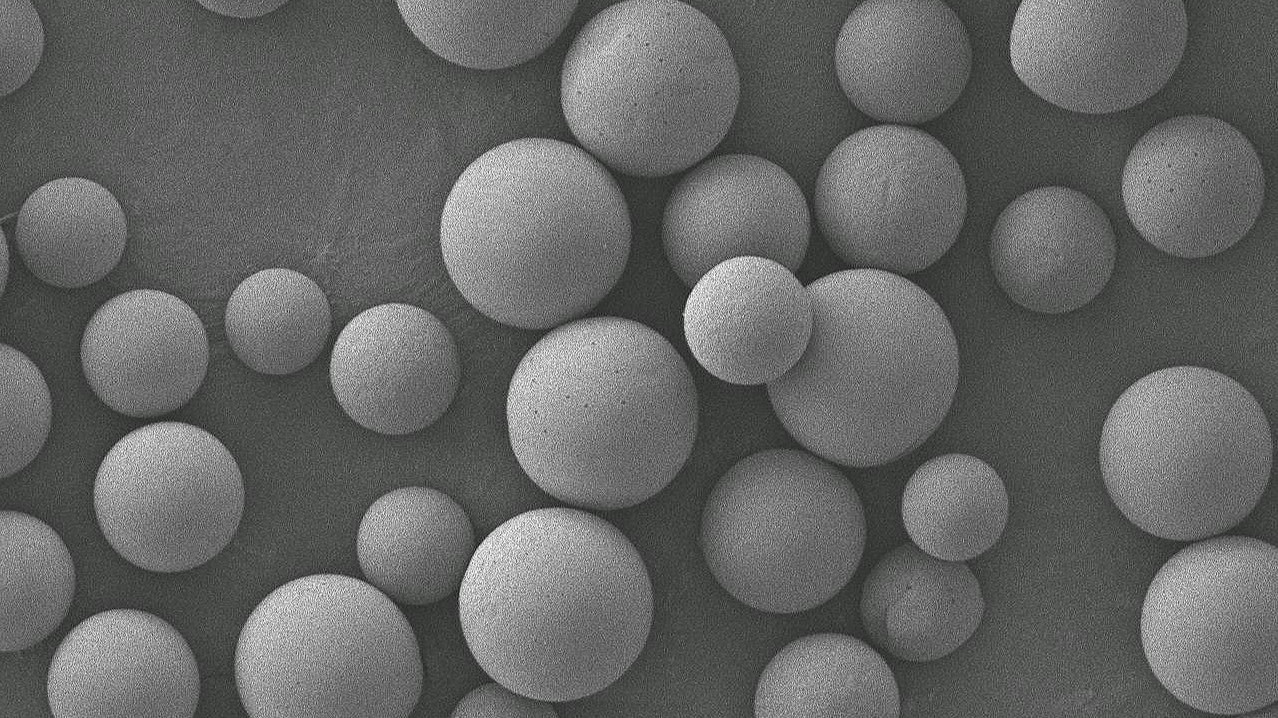

Poly (Lactide-Co-glycolide) (PLGA) is a biodegradable synthetic polymer with good biocompatibility and degradability. It can be degraded into lactic acid and glycolic acid in the body, participate in human metabolism, and finally form carbon dioxide and water to be excreted from the body. Its degradation cycle can range from several weeks to several years by adjusting the ratio of glycolide and lactide. It has been approved by the US FDA for use in clinical medicine and has a variety of products on the market. At present, the application of PLGA in drug sustained-release tissue engineering scaffolds, absorbable sutures, anti-adhesion membranes, bone implants, and ultrasound contrast agents has been widely studied, and its application potential in the biomedical field is huge.

The safety of PLGA as a biomedical material is of vital importance. We used lactide and glycolide as monomers and synthesized PLGA through bulk ring-opening polymerization. Ethyl acetate, dichloromethane, acetone, and ethanol were used in the monomer purification and polymer refining processes. To ensure that the residual amount is within the safe use limit, it is necessary to establish a method for determining the residual solvent of PGA. At present, the determination method of solvent residue is mostly used in drugs, and there is little research on polymer materials. To this end, this study used a capillary column to determine the solvent residue of PGA75/25 and PLGA50/50 (the lactide to glycolide ratio is 75:25 and 50:50, respectively) by headspace injection, and established a corresponding determination method.

II. Materials and methods

01. Instruments and reagents

Agilent 6890N gas chromatograph (FD detector); Agilent 7697A automatic headspace sampler.

Ethanol, ethyl acetate, and methylene chloride are all chromatographically pure; acetone is analytically pure; dimethyl sulfoxide is chromatographically pure. PLGA50/50 (molar ratio of lactide to glycolide 50:50), homemade, batch number: 17061401, 17091302; PLGA 75/25 (molar ratio of lactide to glycolide 75:25), homemade batch number: 17102401.

02. Chromatographic conditions

DB-624 capillary column (30m x 530μm x 3.0μm), column temperature: initial temperature 100℃, maintained for 5min, then increased to 180℃ at a rate of 30℃/min; injection port temperature: 200℃; detector temperature: 250℃; carrier gas: N2, flow rate 3.0m/min; split ratio 10:1; headspace heater temperature: 100℃; quantitative valve temperature: 110℃; transmission line temperature: 120℃; headspace bottle equilibration time: 20min; injection volume: 1mL.

03. Preparation of standard solution

Take 1.0g of ethanol, acetone and ethyl acetate, weigh them accurately, and place them in the same 100mL volumetric flask; take 1.2g of dichloromethane, weigh it accurately, dissolve it in dimethyl sulfoxide and make it up to 100mL, accurately measure 10mL, place it in the above volumetric flask, dilute it with dimethyl sulfoxide and make it up to the standard stock solution.

Accurately measure 5 ml of the standard stock solution, place it in a 50 mL volumetric flask, dilute it with dimethyl sulfoxide and make it up to volume as the standard solution.

04. Sample solution preparation

Take 1.0g of glycolide-lactide copolymer, weigh accurately, place in a headspace bottle, add 5ml of dimethyl sulfoxide and seal until completely dissolved, as the sample solution.

III. Results

01. Selection of chromatographic column type and headspace equilibrium conditions

Ethanol, acetone, dichloromethane, and ethyl acetate all have certain polarity. According to the principle of "like dissolves like", the Agilent DB-624 capillary column was selected for determination. The stationary phase of the Agilent DB-624 capillary column is equivalent to the USP stationary phase G43, with medium polarity. The effect of headspace equilibrium time of 10, 20, and 30 min on the determination of residual solvents was investigated. It was found that the gas-liquid phase of each component reached equilibrium in 20 min, as shown in Figure 1. Therefore, combined with the air tightness of the headspace bottle, the headspace temperature of 100℃ and the equilibrium time of 20 min were finally selected.

Fig.1. The curve of peak area with the equilibration time

02. System suitability

Take 5mL of standard solution and place it in a headspace bottle, seal it, balance the injection under headspace conditions, record the chromatogram, and the results are shown in Figure 2. As can be seen from the figure, the peak order is ethanol, acetone, dichloromethane, and ethyl acetate, and the separation between the peaks of each component is greater than 1.5, and the four solvents are well separated.

Fig.2. Gas chromatogram of various solvents

03. Precision

Take 5 ml of the standard solution and place it in a headspace bottle, seal it, and balance the injection under headspace conditions. Inject it 6 times in succession, and calculate the relative standard deviation (RSD) of each control peak area. The results show that the RSD values of ethanol, acetone, dichloromethane and ethyl acetate are 1.65%, 0.91%, 1.81% and 1.08% respectively, with good precision.

04. Linearity and range

Precisely measure 0.2, 0.4, 0.6, 0.81.0, 1.2, and 1.5 mL of standard stock solution, respectively, and place them in a 10 mL volumetric flask, dilute with dimethyl sulfoxide and make up to volume to prepare a series of linear test solutions. Take 5 mL of each and place them in a headspace bottle and seal them. Balance the injection under headspace conditions, and establish a linear regression equation with peak area (A) as the ordinate and concentration (c, mg/mL) as the abscissa, as shown in Table 1. The results show that ethanol, acetone, and ethyl acetate are all in the range of 0.2~1.5 mg/mL, and dichloromethane is in the range of 0.024~0.18 mg/m with good linear relationship with their respective peak areas.

Table 1. The linear equations and correlation coefficients of various solvents

05. Detection limit and quantification limit

Take an appropriate amount of ethanol, weigh it accurately, place it in a 10mL volumetric flask, add dimethyl sulfoxide to dissolve and make up the volume, shake well, then dilute it step by step, accurately measure 5mL of the diluted solution, place it in an empty bottle at the top, seal it, and inject it according to the chromatographic conditions in Section 2.2. The detection limit of ethanol is S/N≥3, and the quantification limit of ethanol is S/N≥10. The detection limit and quantification limit of acetone, dichloromethane and ethyl acetate are determined in the same way. The results are shown in Table 2.

Table 2. The detection limits and quantitativelimits of various solvents

06. Recovery rate

Using the sample addition recovery method, accurately measure 4, 5, and 6 mL of the standard stock solution, place them in 50 mL volumetric bottles, dilute with dimethyl sulfoxide to the fixed volume, shake well, and use them as 80%, 100%, and 120% recovery rate control solutions. Take about 1.0g of the sample, weigh it accurately, place it in a headspace bottle, add 5 mL of the 80% recovery rate control solution accurately, seal it, wait until the sample is completely dissolved, and prepare 3 copies in parallel as the 80% recovery rate sample solution; prepare 100% in the same way and 120% recovery rate sample solution; prepare the sample solution according to the method in 2.4, and measure the peak areas of the recovery rate sample solution, sample solution and recovery rate control solution according to the method in Section 2.2, and calculate by the peak area according to the external standard method. IV. The test results of various solvent recovery rates are shown in Table 3.

Table 3. Results of recovery test of solvents

As can be seen from Table 3, the average recovery of ethanol was 99.50% with an RSD value of 1.78%, the average recovery of acetone was 98.54% with an RSD value of 1.96%, the average recovery of dichloromethane was 98.89% with an RSD value of 1.38%, and the average recovery of ethyl acetate was 99.14% with an RSD value of 1.57%.

07. Sample Assay

Prepare the sample solution according to Section 2.4, balance the injection under headspace conditions, and record the chromatogram. Calculate the contents of ethanol, acetone, dichloromethane and ethyl acetate in PLGA by peak area according to the external standard method. The assay results of three batches of samples are shown in Table 4.

Table 4. Assay results of three batches ofsamples

According to the requirements of the "Common Residual Solvents and Limits in Drugs" in the General Rules of the Fourth Part of the 2015 Edition of the Chinese Pharmacopoeia, the limits of ethanol, acetone and ethyl acetate are all 0.5%, and the limit of dichloromethane is 0.06%. As shown in Table 4, the residual amounts of ethanol, acetone and ethyl acetate in the three batches of samples are all less than 0.5%, and the residual amount of dichloromethane is less than 0.06%, indicating that the residual organic solvents in the samples are effectively controlled.

IV. Discussion

PLGA is widely used as a biomedical material. During its synthesis, whether the monomer is purified by recrystallization or the polymer is purified by dissolution-precipitation method to remove catalysts or small molecule residues, unreacted monomers, etc., organic solvents are introduced. Commonly used solvents include methylene chloride, ethanol, acetone, ethyl acetate, etc. This study used headspace gas chromatography to simultaneously measure the residual amounts of each solvent in PLGA, and established a method for determining the residual solvent amounts.

In the methodological study, dimethyl sulfoxide was selected as the solvent. This solvent not only has a boiling point much higher than the four solvents to be tested, but also has good solubility in PLGA. The gas chromatogram (Figure 2) shows that the chromatographic peaks of dimethyl sulfoxide and each solvent are well separated, and there is no interference with the determination of each solvent. At the same time, the separation between each solvent is greater than 1.5, indicating that the specificity of this chromatographic condition is good. Secondly, the headspace bottle equilibrium time in the chromatographic conditions was studied, and the results showed that 20 minutes is more appropriate. In addition, ethanol, acetone and ethyl acetate all have good linear relationships with their respective peak areas in the range of 0.2 ~ 1.5 mg/mL. Dichloromethane has a good linear relationship in the range of 0.024~0.18mg/mL. The detection limit and quantification limit of each solvent are 0.09~0.31mg/mL and 0.16~1.17μg/mL respectively. The precision RSD is less than 2%, and the recovery rate is 98.54%~99.50%, RSD is less than 2%. The study showed that the method has strong specificity, good reproducibility and high sensitivity, and can be used to determine the residual amounts of ethanol, acetone, dichloromethane and ethyl acetate in biodegradable polyester PLGA.

The established method was used to test two batches of homemade PLGA50/50 and one batch of PLGA75/25 samples. The results showed that the residual amounts of ethanol, acetone, dichloromethane and ethyl acetate in the three batches of samples were all within the safety limits specified in the pharmacopoeia, which achieved accurate detection of the residual solvents in homemade PLGA materials and kept the residual amounts of each solvent within safety limits.

Dongguan Fortune Medical Technology Co., Ltd. (Introduction to absorbable polymer materials)

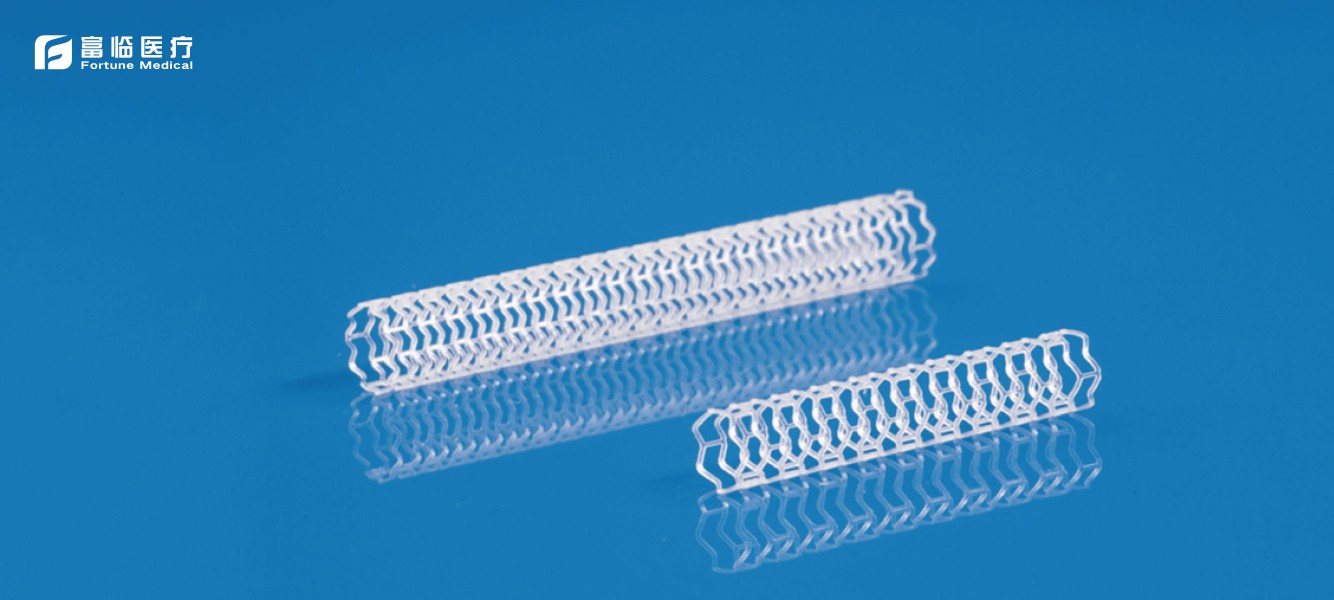

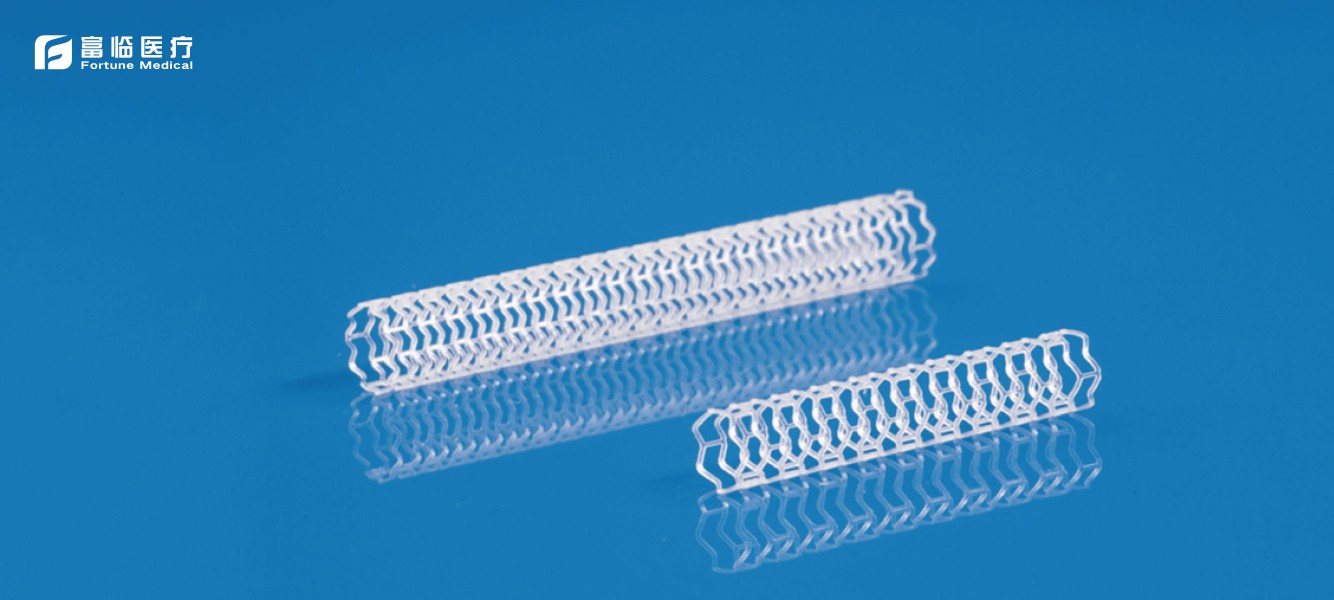

Dongguan Fortune Medical Technology Co., Ltd. is based on medical monomers and medical degradable polymer polyester materials (biomaterials), with interventional non-implantable devices (absorbable devices) as the core, providing customers with integrated, End-to-end high-end consumables R&D and production services continue to lower the R&D threshold for absorbable medical devices and help customers improve R&D efficiency. Bring more breakthrough treatment plans to patients, and the service scope covers the research and development and production of medical monomers, medical degradable polymer polyester materials (biomaterials), medical absorbable monofilaments/multifilaments, and absorbable medical devices.

In terms of polymer degradable materials, our technical core is based on years of accumulation, and we have mature and proven technical reserves. We have become a pioneer and leader in the Chinese absorbable materials market.

-

Quantitative Detection Method for Residual Monomer in Polylactic Acid

Polylactic acid has good biocompatibility and degradability, good thermoplasticity and high strength. It can be processed into various medical products. It has been widely used in medical device products such as fracture internal fixation and bone repair, degradable stents, absorbable sutures, tissue engineering stents, 3D printing implants, etc.2025-01-04

-

Application of biodegradable polymer materials in medical devices

The performance and degradation characteristics of several commonly used biodegradable polymer materials are reviewed, including polyglycolide,polylacticacid,(glycolide-lactide) copolymer,polycaprolactone,polydioxanone,polyhydroxyalkanoate, polytrimethylene carbonate, polyurethane and polyether urethane, etc., and their applications in medical devices, including implants, tissue engineering scaffolds, drug controlled release carriers, etc. are reviewed.2025-01-04

-

Method for determination of monomer residues in biodegradable polydioxanone materials

Establish a gas chromatography method for testing the residual monomer dioxanone in polydioxanone raw materials. A DB-624 capillary column (30.0 m ×535 μm ×3.00 μm) was used, and the temperature was programmed (146 ℃ for 5 min, 30 ℃/min to 200 ℃, and maintained for 2 min).2025-01-04